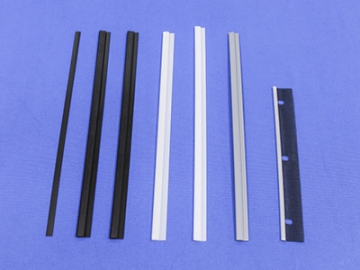

Custom Plastic Profiles

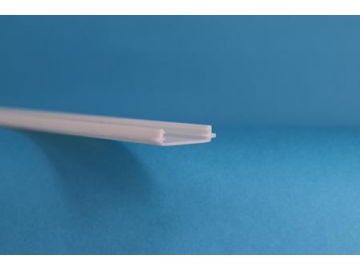

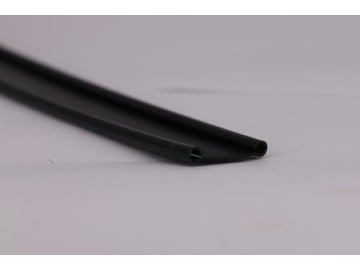

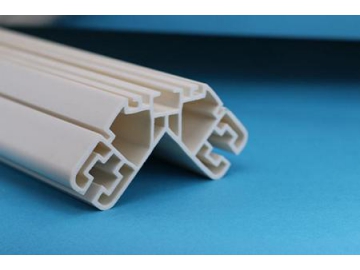

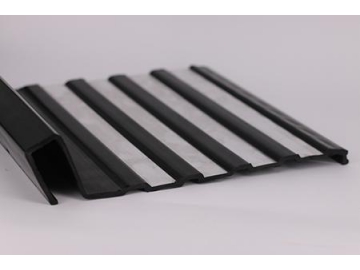

SHINYU provides various plastic profiles for the manufacturers, distributors and traders in furniture industry, electric appliance industry, exhibition equipment industry, architectural material industry, communication industry and so on. Our main products include shaped plastic extrusion, plastic tube, plastic bar, trim strip, sealing strip, LED lampshade, plastic-steel rod, and other rigid and flexible plastic products. We can customize products with various shapes within maximum size(500mm*20mm).

SHINYU produces plastic extrusion profiles which use standard-type plastic with SGS report certificate as raw materials, and we set standard incoming inspection for all of these materials. Material quality is very important for the quality of plastic extrusion, so our product quality can be ensured.

Our main materials:PVC, ABS, PS, PP, PE, PC, PMMA, TPE, TPR , TPV and TPU.

SHINYU has19-year experience in customizing mold to produce plastic extrusion profiles for our customers, we have a complete set of mold research and processing process.

Up to now, we have independently finished the design and manufacturing of more than 2000-set molds.

We own a specialized design team of 5 senior engineers, among of them, two engineers have already 20-year experience in plastic industry.

In the form of mold processing, SHINYU has complete manufacturing and production equipment, we have three high-speed wire cutting machines which can ensure our processing precision to positive and negative 20mm.

Besides, for some products required very high precision, we will contact external professional mold processing center to meet the required high precision.

SHINYU has19-year experience in producing plastic extrusion profiles, we can customize plastic extrusion profiles for customers in various industries.

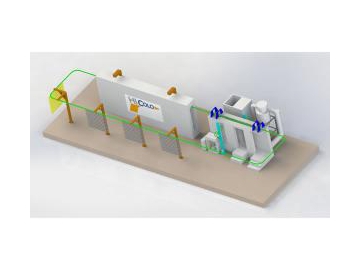

In the form of extrusion, SHINYU has more than 20 plastic extrusion production line, which can monthly produce more than 800tons plastic profiles at maximum. And we are now introducing more machines to the increasing quantity demanded by customers.

SHINYU strictly obey the delivery time, it is also why our customers choose SHINYU in the long term.

SHINYU can not only provide normal plastic extrusion technology, we can also provide you with co-extrusion technology combining materials with 3-kind textures or 3-kind colors.

Surface treatment we can provide: heat stamping, embossing, spray, and various wood grain/figure/logo customization.

Surface treatment we can provide: heat stamping, embossing, spray, and various wood grain/figure/logo customization. Follow-up treatment we can provide: punching, trimming, rubberizing, or follow-up treatment after finished products assembly. And we can provide customized treatment according to your requirements.

Follow-up treatment we can provide: punching, trimming, rubberizing, or follow-up treatment after finished products assembly. And we can provide customized treatment according to your requirements. Slitting: we own more than 20 automatic slitting machines, the slitting precision can up to positive and negative 0.2mm.

Slitting: we own more than 20 automatic slitting machines, the slitting precision can up to positive and negative 0.2mm. Packing and transportation: usually, we use carton as packaging material, but we can also add foam mat or wooden frame inside to protect products according to your requirements.

Packing and transportation: usually, we use carton as packaging material, but we can also add foam mat or wooden frame inside to protect products according to your requirements.

- Customer provides product drawing or sample plate.

- SHINYU provides related mold and our quoted price.

- Customer confirms the price and pays for subscription.

- SHINYU finish the development of mold and formula.( Normally 10 days)

- Customer confirms the sample plate.

- Final order issued.

- Delivery of products.