Extrusion Press

Aluminum Extrusion Press, Metal Forming Press, Aluminum Extrusion System

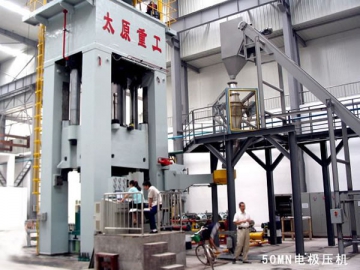

Since 1962, our company has been studying extrusion press and successively launched nearly 400 sets of extrusion press for aluminum, copper, magnesium, steel and carbon. Extrusion presses offered by our company range from 5MN to 235MN, accounting for 80% of the medium- and large-scale extrusion presses on China's market.

-

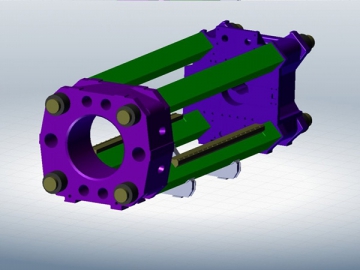

The prestressed combination frame increases structural strength and overall stiffness of the extrusion press, thus ensuring the quality of product.

-

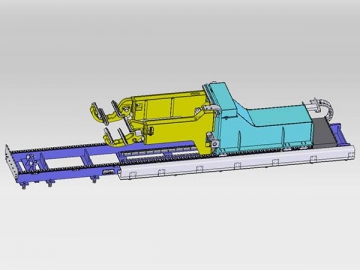

Short-stroke structure: frame is much higher stiffness; decreases the consumption of hydraulic oil, increasing the accuracy of speed control and pressure control; cutting the dead cycle time.

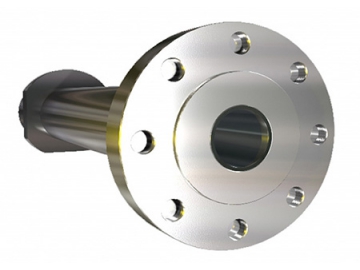

Front loading system: Billet center is consistent with container center and realizes non-friction loading; Billet is upset symmetrically, leading to great improvement in gas exhausting, avoiding explosion and increasing the extruding product's quality.

-

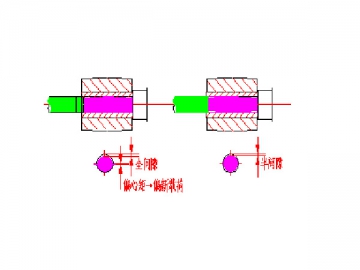

Adjustment of container and moving crosshead.

Horizontal and vertical four-side guiding structure is used for container and moving crosshead. along with a built-in gap adjusting device, for easy, precise and convenient alignment

-

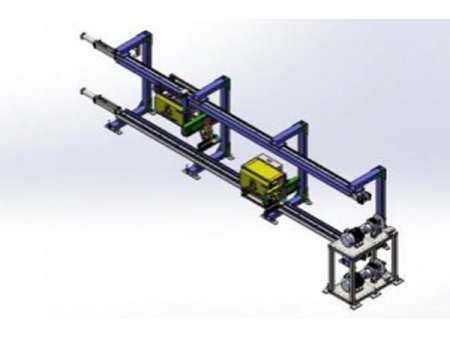

High efficient auxiliary machine: The automatic length-measure billet pusher and telescopic self-adapting billet loader both ensure efficient and orderly material supply. the return distance of container and stem can be controlled according to actual billet length maximum reducing the dead cycle time.

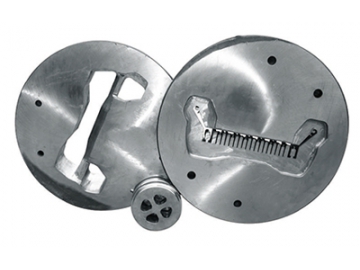

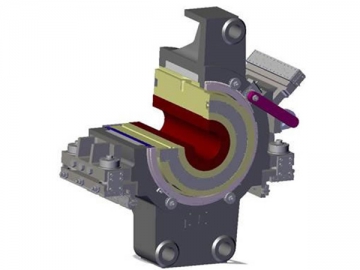

A series of innovative devices are equipped for reducing the tool exchanging time and improving the work efficiency, such as stem fast changing device, container fast changing device, container support cyclinder, die fast changing device and more.

By using a fixed dummy block, the extrusion press gets rid of the block circulation system and reduces the non-working operation time, thereby cut down the power consumption and increasing the production efficiency. Not only that, the dummy block can be kept at a relatively constant temperature and benefits the billet extrusion.

-

-

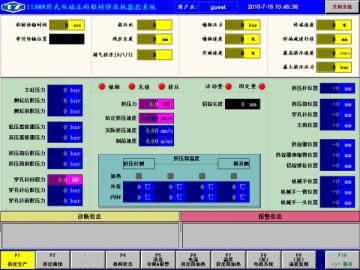

The combination of master computer and PLC system realizes dynamic display of component position, pressure, oil temperature, oil level, hydraulic circuit simulation, extrusion curve graph, parameters setting, motor control and extrusion cylinder heating control.

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Handling system, aging Furnace, gas furnace |

| 12.5 MN extrusion press | 12.5MN | 16.7 × 8.2 | 3.8 | 330 | 20mm /s | Customized |

| 18MN extrusion press | 18MN | 14.2 × 9.5 | 4.5 | 520 | 20mm /s | |

| 20MN extrusion press | 20MN | 17.6 × 10 | 5.2 | 590 | 20mm /s | |

| 27.5MN extrusion press | 27.5MN | 19.3 × 11.5 | 5.6 | 765 | 20mm /s | |

| 36MN extrusion press | 36 MN | 21.8 × 12 | 6.6 | 975 | 20mm /s | |

| 45MN extrusion press | 45 MN | 22.5 × 14 | 6.7 | 1200 | 20mm /s | |

| 55MN extrusion press | 55 MN | 25.2 × 15.2 | 6.9 | 1520 | 20mm /s | |

| 75MN extrusion press | 75 MN | 31.5 × 16.1 | 7.4 | 2080 | 20mm /s | |

| 90MN extrusion press | 90 MN | 32.7 × 18.3 | 7.5 | 2300 | 20mm /s | |

| 125MN extrusion press | 125 MN | 40 × 21 | 8.5 | 2300 | 15mm /s | |

| 150MN extrusion press | 150 MN | 42 × 22 | 8.8 | 3100 | 15mm /s | |

| 175MN extrusion press | 175 MN | 43.4 × 24 | 9 | 4300 | 20mm /s | |

| 225MN extrusion press | 225 MN | 59.5 × 26 | 11.2 | 6200 | 20mm /s | |

| 235MN extrusion press | 235 MN | 57.4 × 27.1 | 12.3 | 4600 | 10mm /s |