Vacuum Belt Continuous Dryer For Liquid

Liquid Dehydrator / Belt Dryer / Tray Dryer

Overview

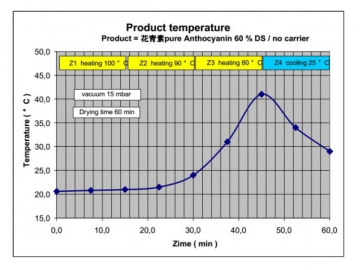

The vacuum belt continuous dryer for liquid is designed to solve the problems associated with extracting highly concentrated materials in viscous products. Traditionally, a centrifugal spray dryer would damage the thermally sensitive components and lead to materials sticking to the walls of the dryer. Also, regular vacuum ovens are not ideal for these types of operations because the ovens take long periods of time for drying and require large amounts of energy. This tray dryer is ideal because it features a low drying temperature with excellent sanitary features and it can fully meet GMP requirements.

Application

Plant extracts

Fruit juice concentrates

Pharmaceutical products

Coffee, tea, etc.

Soluble dried malt extract

Bakery products

Meat extracts

Advantages

Controlled testing conditions

Short processing time

Continuous and batch processing

Controlled adjustment of end-product properties including bulk density, color and flavor

Scalability for commercial plants

Work Flow

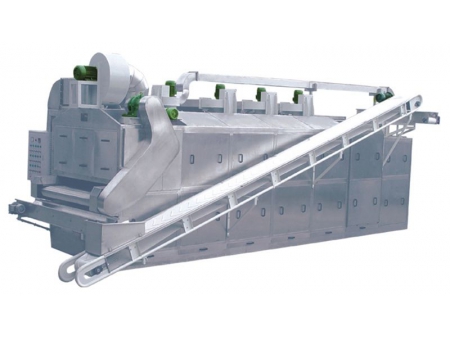

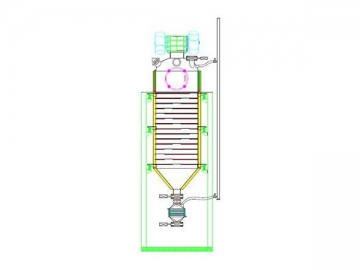

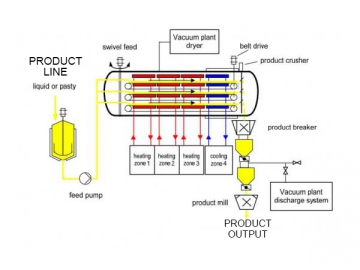

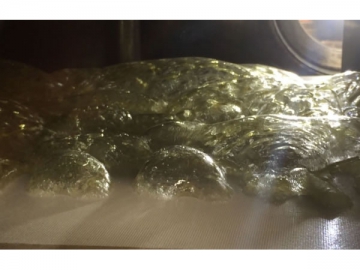

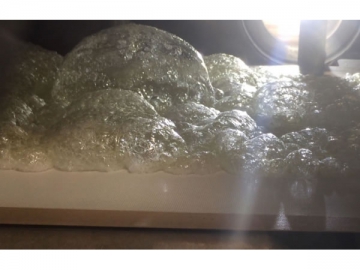

This drying equipment features a vacuum chamber where a material conveying guide belt (Teflon PTFE) is installed. Materials are distributed continuously on the guide belt after they pass through the continuous vacuum distributor at the top of the machine (adjustable distribution thickness 3mm-30mm). The guide belt conveys the material slowly to the other end while the heating zone (40℃-180℃) below the belt evaporates moisture within the compound. Evaporated moisture is quickly removed by the vacuum system. The compound automatically falls onto the second layer guide belt when it reaches the end. The process repeats until the desired dryness is achieved. When it is finished, materials will fall into the conveying chute at the discharging end where a screw conveyor will deliver it to other processing equipment to be ground, sieved and pulverized.

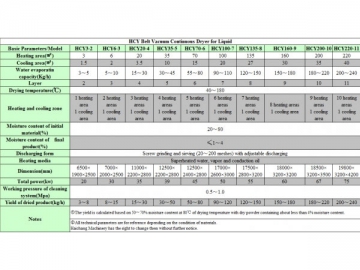

Selection