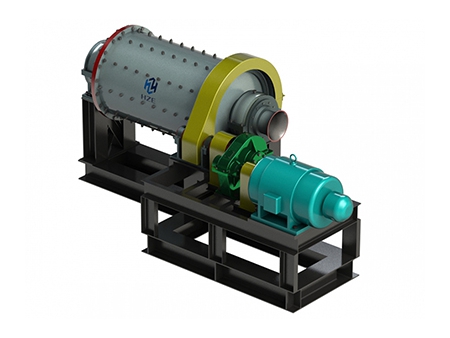

Rod Mill

As its name implies, rod mill is a device which makes use of rods to grind materials to certain fineness. Generally, the length of the steel rods adopted can’t exceed seven meters because overlong rods will cause misalignment and tangle among rods, which will further deteriorate grinding effect. Therefore, commonly used rods aren’t very long and their diameter ranges from 75 to 150mm. According to the method of discharge, rod mill can be divided into overflow type, end peripheral discharge type and center peripheral discharge type, thereby fulfilling various requirements of customers.

Rod mill has a wide range of application. It is often utilized to prevent damage caused by overgrinding in gravity concentration or magnetic separation of tungsten-tin ores and other rare metal minerals in dressing plants. When it comes to a two-stage grinding process where the size of minerals need to be reduced to 1 to 3mm from 6 to 20mm in the first stage, rod mill is able to ensure greater capacity and higher efficiency in the first-stage grinding. However, it fails to compete with a ball mill in the second-stage grinding because a ball has larger superficial area than a rod with the same weight. Sometimes, rod mill can also take the place of a short head cone crusher.

Technical Parameters| Model | Shell Diameter(mm) | Shell Length(mm) | Motor Model | Motor Power (kW) | Motor Rotating Speed (r/min) | Length | Width | Height | Capacity (t/h) | Effective Volume (m3) | Weight |

| (mm) | (mm) | (mm) | (kg) | ||||||||

| 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 | |

| 900 | 2400 | Y250M-8 | 30 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 | |

| 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 | |

| 1500 | 3000 | JR125-8 | 95 | 725 | 7935 | 3185 | 2280 | 5 | 19990 | ||

| 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 | |

| 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 | |

| 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 | |

| 2400 | 3000 | JR138-8 | 280 | 735 | 9004.5 | 4836.4 | 3490 | 11.5 | 55795 | ||

| 2700 | 3200 | JR157-8 | 320 | 750 | 10509 | 5000 | 3620 | 15.7 | 83110 | ||

| 2700 | 3600 | JR158-8 | 380 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 | |

| 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 | |

| 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 | |

| 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 | |

| 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 | |

| 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |