Roll Forming Machine

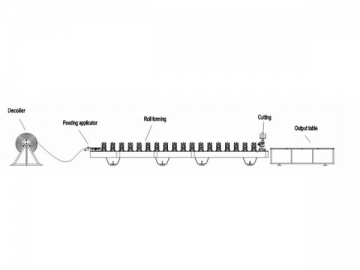

Roll forming machines are comprised of a hydraulic decoiler with a breaking device, roll former with tooling, hydraulic cut-off machine, a run out table and an automatic stacking device. Our roll forming machines are economically friendly, and snap together easily with metal forming equipment. These roll forming systems come in a number of types for different purposes, including roof forming machines, roof tile forming machines, window frame forming machines, door frame forming machines, wall panel forming machines, and floor deck forming machines.

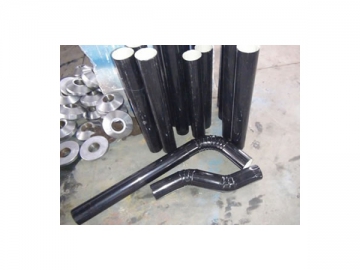

Roll forming systems are also used to form roof panels, shingle nails, glazed tiles, purlins, decks and downpipes and highway guardrails.

Trapezoidal roof roll forming machines are known for their high forming speed, optimum design, easy operation and extreme durability. Roof roll forming machines include hydraulic decoilers with a breaking device, roll former with tooling, hydraulic cut-off machines, run out tables and an automatic stacking device.

Roofing Corrugated Sheet Roll Forming Machine

Thickness: 0.3-0.8mm

Coil width: Custom-made, 1000mm or 1200mm or 1250mm

Yield Strength: 250-350 Mpa

Material : PPGI, Color Steel, GI.

Material width: depend on customer's requirement

Decoiler Type: manual or automatical type (depend on customer's requirement)

Weight Capacity Of Decoiler: 5 Ton

This tile roll forming machine is suitable for coiled metal material, making the required shape after processing through uncoiling, forming continuously, pressing and cutting to length. The roll forming machine uses a PLC controlling system, AC frequency and adjusting-speed technology, in order to achieve continuous production.

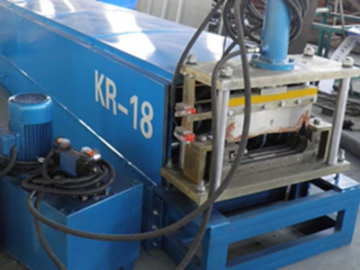

Forming Frame Structure: Guiding Column Slide Blocks; This forming frame structure design has a much higher precision than a wall plate welding structure.

PLC Brand: PANASONIC Brand

Machine Diameter: about 7000mm(L)x800mm(W)x1300mm (H)

Material Spec: Galvanized steel sheet

Thickness of Coil Sheet: 0.7 --1.2 mm

Main Motor Power of Floor decking roll forming machine: 22kw

Forming Speed: 10--12m/min

This crash barrier roll forming machine mainly consists of the decoiler, guide device, levelling system, hydraulic station, punching, roll forming system, cutting system and runout table.

Number of forming station: about 20

Forming speed of square downspout roll forming machine: 6-12m/min

Voltage: 380 V, 3 Phase 50Hz (or depend on customer’s requirement)

Machine dimensions: about 12,000mm x 1,100mm x 1,200mm

Material: GI, Carbon steel

Material thickness: 2-3.0mm

Machine diameter: about 8500x1000x1300mm ( LXWXH )

Weight of machine: about 5 Ton

Decoiler: Manual or hydraulic decoiler ( customer can choose )

Roller material: GCr15 steel, quenched and heated process

Main power: 11KW

Hydraulic power: 5.5KW

Punching: hydraulic punching

Decoiler Type: manual or automatic (depending on customer’s requirement)

Decoiler weight capacity: 3 Tons

Main Motor Power: 5.5 Kw

Hydraulic Motor Power: 3 Kw

Main Axis material: First grade 45# steel, heated and quenched

Roller material: GCr15 Steel, Quenched and heated process

Forming Speed: 0-10 m/min

Dive Type: 1.2” Chain of transmission

A tension meter arrangement is fixed on the housing to tighten the chains. This arrangement is provided to avoid the slag in the chain due to screw down operation.

A feed table is provided with gauge blocks to adjust the width of the sheets. This table is mounted on two brackets attached to the housing at both the sides. This table slides on an entry table.

Features

1. Our roll forming machines are designed with Panasonic PLC and touch screens for data processing and setting.

2. Each machine features a speed of 10 to 20 meters per minute.

3. We can also supply customized roll forming equipment according to customer’s specific requirements.

4. Each machine is known for its high quality, excellent performance, fair price and CE certification.

Process Flow

Decoiling→ feeding→ pressing and forming the shape→ measure the length→ cutting→ receiving the plates