Glass Beads

Request a Quote

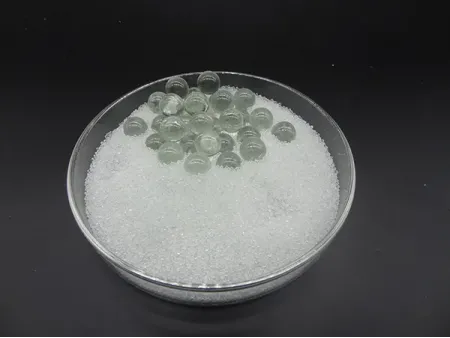

Glass Beads

Glass beads, produced from crushed glass and flat glass materials, are processed into spherical shapes through high-temperature melting. Known for their low thermal conductivity, high strength, and excellent chemical stability, glass beads feature smooth surfaces, uniform sizes, high hardness, and abrasion resistance.

Properties

- High roundness of the beads: >90%

- Roundness: >90%

- Refractive index (glass beads for marking): 1.5-1.9

- Size: 0.045 to 30mm

Applications

- Industrial applications include sandblasting, where the roundness and high purity of glass beads leave surfaces bright and polished. Common sizes: 40#, 60#, 80#, 100#, 120#, 150#, 180#, 220#.

- Glass beads serve as common retroreflective materials for road markings, enhancing visibility and safety at night due to their high reflectivity. Common types: BS6088A, BS6088B.

- Widely used in the textile industry as a common filling material for items like weighted blankets, plush toys, and eye masks. Common sizes: 0.8-1.2mm, 1-2mm, 2-3mm, 3-4mm…

- Larger glass beads, such as 10mm/11mm/12mm, find applications in aerosol and perfume bottle mouths, bearings, and perfume sprayers.

- Glass beads are also utilized in water filtration systems. Common sizes: 3mm±0.03, 5mm±0.03, 8mm±0.03...

Typical Chemical Analysis

| SiO2: >70-75 | Na2O: < 14.0 |

| CaO: >8.0 | MgO: >2.5 |

| Al2O3: >0.5-2.0 | Fe2O3: 0.15 |

Typical Physical Properties

| Shape | Spherical/irregular diamond |

| Specific Gravity | 2.5g/m3 |

| Bulk Density | Approximately 1.5g/cm3 |

| Mohs Hardness | 6-7 |

| Rockwell Hardness | Approximately 46HRC |

Production Flow

- Glass Beads Production Process

- Recycled waste glass collection

- Crushing and screening of the glass

- Production of glass sand, or alternatively, purchasing glass sand

- Metallurgy process

- Screening process

- Packaging