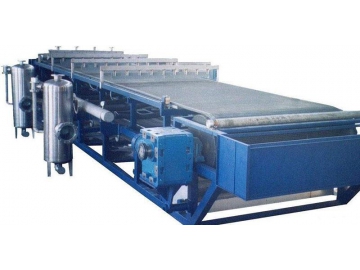

Precision Ceramic Vacuum Filter

Request a Quote

Application

Precision ceramic filter, realizing vacuum dewatering by porous ceramic, can process the materials whose fineness is between -200 to -450 mesh. The vacuum filter is applied to dewater the ore concentrate and tailings of mine materials, oxide in chemical industry, electrolytic residue, leach residue, hearth slag and process waste water, sludge, waste acid and so on in a environmental way.

Applicable materials

Iron ore concentrate, copper ore concentrate, lead ore concentrate, aluminum ore concentrate, nickel ore concentrate, gold ore concentrate, phosphorus ore concentrate, sulfur ore concentrate, gold tailings, nickel gold ore, fluorite ore, acid leaching slag, fine coal, zinc oxide, zinc sulfide, phosphorus concentrate.

| Type | Filter area (m2) | Number of filter disc | Number of filter plate | Volume of tank(m3) | Installed power(KW) | Running power(Kw) | Machine size(L×W×H)(m) | |

| TC-1 | 1 | 1 | 12 | 0.21 | 3.5 | 2.0 | 1.6×1.4×1.5 | |

| TC-4 | 4 | 2 | 24 | 1.0 | 7.0 | 3.0 | 2.4×2.5×2.1 | |

| TC-6 | 6 | 2 | 24 | 1.2 | 7.0 | 6.0 | 2.4×2.9×2.5 | |

| TC-9 | 9 | 3 | 36 | 1.7 | 9.0 | 7.0 | 2.7×2.9×2.5 | |

| TC-12 | 12 | 4 | 48 | 2.2 | 11.0 | 7.5 | 3.0×2.9×2.5 | |

| TC-15 | 15 | 5 | 60 | 2.7 | 11.5 | 8.0 | 3.3×3.0×2.5 | |

| TC-21 | 21 | 7 | 84 | 4.0 | 13.5 | 9.0 | 4.6×3.0×2.6 | |

| TC-24 | 24 | 8 | 96 | 4.5 | 16.5 | 10.5 | 4.9×3.0×2.6 | |

| TC-27 | 27 | 9 | 108 | 5.0 | 17.0 | 11.0 | 5.2×3.0×2.6 | |

| TC-30 | 30 | 10 | 120 | 5.5 | 17.5 | 11.5 | 5.5×3.0×2.6 | |

| TC-36 | 36 | 12 | 144 | 7.0 | 23.0 | 16.0 | 6.6×3.0×2.6 | |

| TC-45 | 45 | 15 | 180 | 8.5 | 25.0 | 19.0 | 7.5×3.0×2.6 | |

| TC-60 | 60 | 15 | 180 | 12.5 | 33.0 | 22.0 | 7.5×3.3×3.0 | |

| TC-80 | 80 | 20 | 240 | 16.2 | 40.0 | 24.0 | 9.0×3.3×3.0 | |

| TC-102 | 102 | 17 | 204 | 18.5 | 53.0 | 35.0 | 8.8×3.6×3.3 | |

| TC-120 | 120 | 20 | 240 | 20 | 60.0 | 40.0 | 9.7×3.6×3.3 | |

| TC-150 | 150 | 25 | 300 | 24 | 75.0 | 47.0 | 11.2×3.6×3.3 |

- The vacuum degree of precision ceramic filter is 0.09-0.098MPa and the moisture of filter cake is low.

- The solid-containing content of applicable materials should be less tan 50ppm.

- Vacuum filter can save more tan 90% energy compared with traditional machines thus it has low operating costs.

- Precision ceramic vacuum filter is more proper for the materials which need to be washed because it adds filter cake washing compared with traditional ceramic filters.

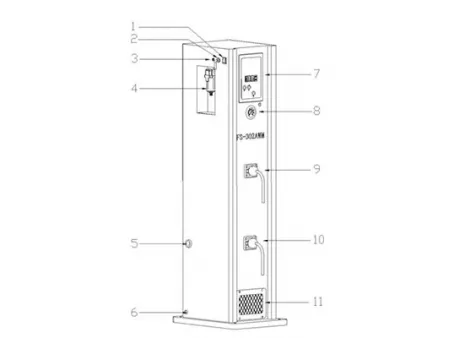

- The vacuum filter adopts PLC control system and micro-computer control system which increase its automation degree.

- The vacuum filter has compact structure, less occupied area and it is convenient to install and repair.

- It can be used in complex working conditions because it is equipped with liquid discharge device.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos