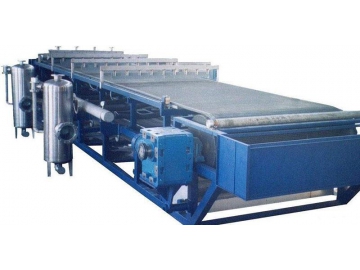

Vertical Automatic Filter Press

Request a Quote

Application

Vertical automatic filter press can realize solid-liquid separation. It is mainly used in dewatering mine materials, smelting and dewatering oxide in chemical industry, electrolytic residue, leaching residue, hearth slag and processing waste water, sludge, waste acid and so on in a environmental way.

Applicable materials

Zeolite, sulfide, lead in compounds, copper slag, waste water calcium sulfate, roasting gold tailings, ultra-fine aluminum hydroxide, copper and nickel ore concentrate, copper ore concentrate, nickel ore concentrate, coal slurry, iron slag, gold tailings by iron flotation, zinc oxide powder.

| Type | Filter area (m2) | Number of filter layers | Overall dimensions (L×W×H) (m) | Weight (T) | Volume m3 (H=45mm) | Hydraulic power (KW) | Size of filter plate (mm) | Width of filter cloth (m) | |

| HVPF-1 | 1 | 2 | 2. 5×1.5×2.0 | 8 | 0.05 | 7.5 | 1000×550 | 0.70 | |

| HVPF-2 | 2 | 4 | 2. 5×1.5×2.2 | 9 | 0.09 | ||||

| HVPF-3 | 3 | 2 | 3. 5×2.5×2.2 | 14 | 0.16 | 11 | 1750×900 | 1.05 | |

| HVPF-6 | 6 | 4 | 3. 5×2.5×2.3 | 15 | 0.27 | ||||

| HVPF-9 | 9 | 6 | 3. 5×2.5×2.5 | 16 | 0.41 | ||||

| HVPF-12 | 12 | 8 | 3. 5×2.5×2.7 | 17 | 0.54 | ||||

| HVPF-15 | 15 | 10 | 3. 5×2.5×2.9 | 18 | 0.68 | ||||

| HVPF-18 | 16 | 12 | 3. 5×2.5×3.1 | 19 | 0.81 | ||||

| HVPF-21 | 21 | 14 | 3. 5×2.5×3.3 | 21 | 0.95 | ||||

| HVPF-24 | 24 | 16 | 3. 5×2.5×3.4 | 22 | 1.08 | ||||

| HVPF-27 | 27 | 18 | 3. 5×2.5×3.6 | 23 | 1.22 | ||||

| HVPF-15 | 15 | 6 | 5.1×3.7×3.3 | 37 | 0.68 | 22 | 2500×1020 | 1.15 | |

| HVPF-20 | 20 | 8 | 5.1×3.7×3.6 | 39 | 0.90 | ||||

| HVPF-25 | 25 | 10 | 5.1×3.7×3.9 | 42 | 1.13 | ||||

| HVPF-30 | 30 | 12 | 5.1×3.7×4.2 | 43 | 1.35 | ||||

| HVPF-35 | 35 | 14 | 5.1×3.7×4.5 | 44 | 1.58 | ||||

| HVPF-40 | 40 | 14 | 5.1×3.7×4.8 | 45 | 1.80 | ||||

| HVPF-45 | 45 | 18 | 5.1×3.7×5.1 | 46 | 2.03 | ||||

| HVPF-50 | 50 | 20 | 5.1×3.7×5.4 | 48 | 2.25 | ||||

| HVPF-55 | 55 | 22 | 5.1×3.7×5.7 | 50 | 2.46 | ||||

| HVPF-60 | 60 | 10 | 6.9×4.5×5.4 | 97 | 2.70 | 37 | 4010×1500 | 1.70 | |

| HVPF-72 | 72 | 12 | 6.9×4.5×5.8 | 100 | 3.24 | ||||

| HVPF-84 | 84 | 14 | 6.9×4.5×6.2 | 104 | 3.78 | ||||

| HVPF-96 | 96 | 16 | 6.9×4.5×6.5 | 110 | 4.32 | ||||

| HVPF-108 | 108 | 18 | 6.9×4.5×6.9 | 112 | 4.86 | ||||

| HVPF-120 | 120 | 20 | 6.9×4.5×7.2 | 118 | 5.40 | ||||

| HVPF-132 | 132 | 22 | 6.9×4.5×7.6 | 120 | 5.94 | ||||

| HVPF-144 | 144 | 24 | 6.9×4.5×7.9 | 123 | 6.48 | ||||

| HVPF-156 | 156 | 26 | 6.9×4.5×8.3 | 126 | 7.02 | ||||

| HVPF-168 | 168 | 28 | 6.9×4.5×8.6 | 130 | 7.56 | ||||

| HVPF-144 | 144 | 16 | 9.2×5.5×6.8 | 142 | 6.48 | 67 | 6020×1500 | 1.70 | |

| HVPF-162 | 162 | 18 | 9.2×5.5×7.2 | 147 | 7.29 | ||||

| HVPF-180 | 180 | 20 | 9.2×5.5×7.5 | 150 | 8.10 | ||||

| HVPF-198 | 198 | 22 | 9.2×5.5×7.8 | 160 | 8.91 | ||||

| HVPF-216 | 216 | 24 | 9.2×5.5×8.2 | 166 | 9.72 | ||||

| HVPF-234 | 234 | 26 | 9.2×5.5×8.5 | 172 | 10.53 | ||||

| HVPF-252 | 252 | 28 | 9.2×5.5×8.8 | 180 | 11.34 | ||||

| HVPF-270 | 270 | 30 | 9.2×5.5×9.2 | 190 | 12.15 |

- Filter plate adopts tower structure and materials will be filtered horizontally.

- Oil tanks are controlled by synchronous intelligent control system.

- The filter press has compact structure, and it is convenient to operate.

- It can finish the process of filtering, extrusion, washing, drying, discharging the cake and filter cloth continuously.

- The filter pressure can be up to 200MPa and the effect is especially obvious for viscous and fine materials and low moisture filter cake.

- The operation of filter press is controlled by full hydraulic pressure thus it will operate stably, reliably and safely.

- Vertical automatic filter press adopts PLC+ touch screen+ automatic valve control system, which increase its automation degree.

- It has low moisture filter cake and high productivity and the work efficiency is several times than traditional filter presses.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos