Lifting Magnets

| Name | Lifting Magnets (Magnetic Lifter) |

| Model | |

| Diameter | 0.7~2.4m |

| Type | Normal temperature type High temperature type High frequency type |

Brief Description

The magnetic chuck, also known as lifting electromagnet or magnetic lifter, is mainly used in metallurgical, mining, mechanical and transportation industries for lifting and moving magnetic materials such as steel and iron. Also, this electromagnetic chuck can be used as a machine hand for holding ferrous metal.

Specifically, our lifting magnet is suitable for handling cast iron ingot, steel ball and all kinds of steel scrap. The ways of excitation of this handling tool includes constant voltage, strong excitation and over excitation.

Our superior lifting magnet with unmatched performance and versatility plays a critical role in YUNTIAN’s development into one of the most trusted electromagnetic crane suppliers in the world.

Main Features of Lifting Magnet

1. This lifting tool comes with complete seal structure, thus ensuring excellent moisture resistance.

2. Optimal design by computer ensures reasonable structure, light deadweight, strong attraction force and low energy consumption.

3. Magnet exciting coil has been processed by special technology. As a result, the electrical and mechanical property of the coil is improved, heat resistant grade of insulated materials is up to C and integral insulation grade reaches H. Thus, the coil boasts long service life.

4. The rated on-load factor of general lifting magnet has been increased from 50% to 60%, thus improving service efficiency.

5. High temperature type lifting magnet employs unique heat resistant method. Consequently, the temperature of held materials increases from 600°C to 700°C, expanding application range of the electromagnet.

6. Our magnetic lifter holds a feature of simple and convenient installation, operation and maintenance.

Notes

1. If temperature of the materials to be handled is less than 100°C, please use normal temperature type magnetic lifter. Conversely, if the temperature is more than 100°C, please select high temperature type. If temperature is above 600°C, please particularly notice us.

2. When on-load factor exceeds 60%, please choose high frequency type magnetic chunk.

3. When handling materials in water, please choose submerged type (diving depth≤100m). The parameters of submerged type magnet are same as that of normal temperature type. If requiring this type, please specify when ordering.

4. Ambient temperature: Normal temperature type: -50~40°C; high temperature type: -5~80°C. Height above sea level can not exceed 2000m.

5. Equipment matching: The power of rectification control equipment (current) is equal to or larger than the sum of cold-state power of single unit or multi units.

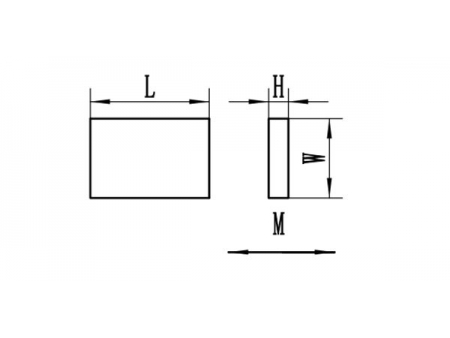

| Models | Electric current (A) | Cold-state power (Kw) | Lifting capacity (Cold/hot state) (kg) | Weight (kg) | Overall dimensions (mm) | ||||||

| Steel ball | Steel ingot | Steel scrap | A | B | C | D | E | ||||

| 15 | 3.3 | 2500 | 380/200 | 120/100 | 490 | 700 | 800 | 160 | 90 | 30 | |

| 18 | 3.96 | 3000 | 480/250 | 150/130 | 620 | 800 | 800 | 160 | 90 | 30 | |

| 26.6 | 5.9 | 4500 | 650/400 | 250/200 | 800 | 900 | 1090 | 200 | 125 | 40 | |

| 35 | 7.7 | 6500 | 1000/800 | 450/400 | 1350 | 1100 | 1140 | 220 | 150 | 45 | |

| 45.5 | 10 | 7500 | 1300/1000 | 600/500 | 1700 | 1200 | 1100 | 220 | 150 | 45 | |

| 54 | 12 | 8500 | 1400/1100 | 700/600 | 2010 | 1300 | 1240 | 250 | 175 | 50 | |

| 71.2 | 15.6 | 11000 | 1900/1500 | 1100/900 | 2830 | 1500 | 1250 | 350 | 210 | 60 | |

| 75 | 16.5 | 12500 | 2300/1800 | 1300/1100 | 3200 | 1650 | 1590 | 370 | 230 | 75 | |

| 102 | 22.5 | 14500 | 2750/2100 | 1600/1350 | 4230 | 1800 | 1490 | 370 | 230 | 75 | |

| 129 | 28.4 | 21000 | 3500/2800 | 2200/1850 | 7000 | 2100 | 1860 | 400 | 250 | 80 | |

| 154 | 33.9 | 28000 | 4800/3800 | 2850/2250 | 9000 | 2400 | 2020 | 450 | 280 | 90 | |

| Models | Electric current (A) | Cold-state power (Kw) | Lifting capacity (Cold/hot state) (kg) | Weight (kg) | Overall dimensions (mm) | ||||||

| Steel ball | Steel ingot | Steel scrap | A | B | C | D | E | ||||

| 26.7 | 6.1 | 6500 | 1050/800 | 450/400 | 1500 | 1100 | 1270 | 220 | 150 | 45 | |

| 36 | 7.4 | 7500 | 1300/1000 | 600/500 | 1850 | 1200 | 1220 | 220 | 150 | 45 | |

| 40.7 | 9 | 8500 | 1450/1100 | 700/600 | 2280 | 1300 | 1290 | 250 | 175 | 50 | |

| 51.4 | 11.3 | 11000 | 1980/1500 | 1100/900 | 3180 | 1500 | 1360 | 350 | 210 | 60 | |

| 55.6 | 12.2 | 12500 | 2300/1800 | 1300/1100 | 3840 | 1650 | 1670 | 370 | 230 | 75 | |

| 73.9 | 16.3 | 14500 | 2850/2200 | 1650/1400 | 4690 | 1800 | 1600 | 370 | 230 | 75 | |

| 98.5 | 21.7 | 21000 | 2300/1900 | 2300/1900 | 7500 | 2100 | 1900 | 400 | 250 | 80 | |

| 117.6 | 25.9 | 26000 | 4850/3900 | 2950/2350 | 9800 | 2400 | 2100 | 450 | 280 | 90 | |

| Models | Electric current (A) | Cold-state power (Kw) | Lifting capacity (Cold/hot state) (kg) | Weight (kg) | Overall dimensions (mm) | ||||||

| Steel ball | Steel ingot | Steel scrap | A | B | C | D | E | ||||

| 12.77 | 2.8 | 2500 | 380/200 | 120/100 | 520 | 700 | 820 | 160 | 90 | 30 | |

| 16.1 | 3.54 | 3000 | 480/250 | 150/130 | 650 | 800 | 820 | 160 | 90 | 30 | |

| 20.5 | 4.5 | 4500 | 600/400 | 250/200 | 900 | 900 | 1110 | 200 | 125 | 40 | |

| 27.5 | 6 | 6500 | 1000/800 | 450/400 | 1500 | 1100 | 1350 | 220 | 150 | 45 | |

| 33.6 | 7.4 | 7500 | 1300/1000 | 600/500 | 1800 | 1200 | 1280 | 220 | 150 | 45 | |

| 40.6 | 8.9 | 8500 | 1400/1100 | 700/600 | 2100 | 1300 | 1280 | 250 | 175 | 50 | |

| 51.4 | 11.3 | 11000 | 1900/1500 | 1100/900 | 3200 | 1500 | 1620 | 350 | 210 | 60 | |

| 60.6 | 13.3 | 12500 | 2300/1800 | 1300/1100 | 3500 | 1650 | 1630 | 370 | 230 | 75 | |

| 95 | 20.9 | 14500 | 2750/2100 | 1600/1350 | 4500 | 1800 | 1510 | 370 | 230 | 75 | |

| 104 | 22.9 | 21000 | 3500/2800 | 2200/1850 | 7550 | 2100 | 1910 | 400 | 250 | 80 | |

| 118.6 | 26 | 26000 | 4800/3800 | 2850/2250 | 9700 | 2400 | 2080 | 450 | 280 | 90 | |

| Models | Electric current (A) | Cold-state power (Kw) | Lifting capacity (Cold/hot state) (kg) | Weight (kg) | Overall dimensions (mm) | |||||

| Steel ingot | Steel scrap | A | B | C | D | E | ||||

| 110/76 | 31.9/15.2 | 2200/1900 | 1000/800 | 4200 | 2000 | 1500 | 1300 | 250 | 180 | |

| 195/135 | 56.6/27 | 3400/2850 | 1500/1250 | 5700 | 3000 | 1500 | 1570 | 310 | 210 | |

| 113/78 | 32.7/15.5 | 2550/2000 | 1150/900 | 5000 | 1800 | 1600 | 1500 | 310 | 210 | |

| 179/123 | 51.9/24.5 | 5000/4200 | 2300/1800 | 8400 | 2500 | 2000 | 2000 | 390 | 280 | |

| 54.5 | 12 | 1450/1100 | 750/600 | 2300 | 1400 | 1000 | 1120 | 220 | 140 | |