Cast Film Line (200m/min)

Request a Quote

View All: http://jd-machine.com

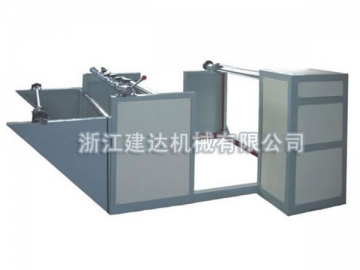

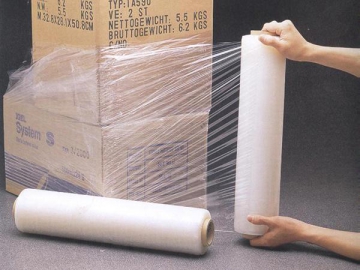

This high speed stretch film extrusion machine is our 4th generation stretch film production line, and features a high speed that can produce rolls of film in a width of 1500mm (500mm x 3 rolls) or 2000mm (500mm x 4 rolls). It uses LLDPE and LDPE granules to produce the casting stretch film, which in turn is widely used as packing material for construction parts, pallet wrapping, auto parts, hardware and more.

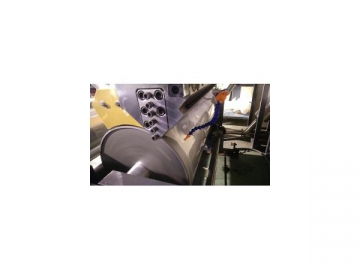

The film extrusion machine is equipped with extruders, T-die, distributor part, traction part, leveling part, edge trimming and recycling part, automatic cutting and winding part as well as an electric control system.

- The cast film line uses a twin screw extruder, and will stick only on one side of the plastic film.

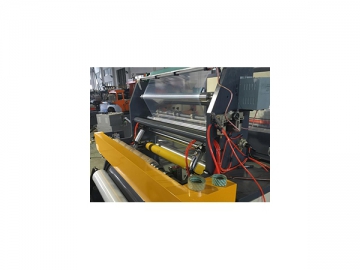

- The cast film line works at a speed of 150 m/min and is controlled by a PLC system with a touch screen. It is easy to operate and features a high efficiency.

- This cast film line will automatically recycle edge strips online in order to save production costs. Recycling is computer controlled, thus reducing labor intensity and improving production efficiency.

- The wrap film winder is controlled with a PLC system, which reduces labor intensity and improves the efficiency.

Waste edges of film online recovery system

Waste edges of film online recovery system  Hydraulic drive net changer; corona treatment device; edge locking device.

Hydraulic drive net changer; corona treatment device; edge locking device.  Flying cutter with servo motor control

Flying cutter with servo motor control

| Model | JDCPE90/60-1000 | JDCPE110/60-1500 | JDCPE130/80-2000 |

| Diameters of screws | Φ90mm Φ60mm | Φ110mm Φ60mm | Φ130mm Φ80mm |

| Ratio of length to diameter | 33:1 | 33:1 | 33:1 |

| Product widths | 500-1000mm(500×2 rolls) | 500-1500mm(500×3 rolls) | 500-2000mm(500×4 rolls) |

| Product thickness | 0.01-0.03mm | 0.015-0.04mm | 0.015-0.04mm |

| Actual working speed | 150m/min | 150m/min | 150m/min |

| Mechanical design speed | 200m/min | 200m/min | 200m/min |

| Maximum yield | 170kg/h | 240kg/h | 300kg/h |

| Main motor power | 55kw 22kw | 90kw 30kw | 110kw 45kw |

| Total power | 180kw | 230kw | 270kw |

| Weight | 9000kg | 11000kg | 13000kg |

| Sizes | 12000mm×5000mm×4000mm | 13000mm×6000mm×4000mm | 14000mm×6000mm×4000mm |

| Power supply | 380V/3P/4L/50Hz | 380V/3P/4L/50Hz | 380V/3P/4L/50Hz |

- The cast film line can be customized according to customer requirements. Products can be customized within 1 or 2 meter widths, and a range of 2 to 7 layers to meet different market needs.

- The shape and technical parameters of this equipment is subject to change without notice, due to the continuous improvements to our machines.

For machinery wrapping

For machinery wrapping  For hand wrapping

For hand wrapping  For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping  For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping - For fresh food/fruit/salad packing

- For fresh food/fruit/salad packing

- For fresh food/fruit/salad packing

- Magical use: For loosing weight

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos