Semi-automatic Edgebander for Door Frame, HKJ-350CU

| Total power | 19KW |

| Dimension (L*W*H) | 3800*900*1560mm |

| Feed speed | 18-22m/min |

| Edge thickness | 0.4-3mm |

| Panel thickness | 10-60mm |

| Panel length | ≥120mm |

| Panel width | ≥95mm |

| Working pressure | 0.6Mpa |

| Min. panel size (L*W) | 120*95mm |

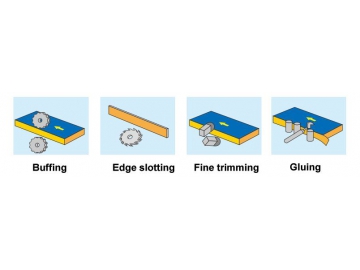

This semi-automatic edgebander is especially designed for making door frame, the feed speed can reach 18-22m/min. With functions of gluing, fine trimming, grooving and buffing, the edge banding machine can guarantee high quality of edge banded pieces. An independent operation panel makes the machine operation and maintenance more easier, saves labor cost and enhances work efficiency.

The grooving unit is used for direct grooving on top, bottom or sides of the door panel, this edgebander is also suitable for manufacturing wardrobe doors and aluminum edge banded doors.

-

Gluing unit is equipped for evenly applying hot melt glue on workpiece edges, it provides an excellent adhesion.

-

Fine trimming unit perfectly removes upper and lower overhanging edges to give a smooth looking edging.

-

Grooving unit for direct grooving on top, bottom and sides of panel, ensuring higher work efficiency.

-

Buffing unit improves panel finishing by polishing of the panel edges while eliminating glue residues.