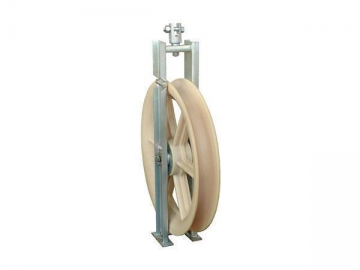

Suspension Assembly for OPGW

Cable Assembly / OPGW Installation / Fiber Optic Cabling

Features

a. The suspension assembly for OPGW features large contact areas between the suspension clamp and OPGW cable for uniform stress distribution and excellent cable protection.

b. Good dynamic stress. It can provide enough grip strength (14~18%RTS) to ensure the safety of the OPGW cable under long unbalanced loads.

c. Overhanging angle: 15°~18°.

d. Flexible rubber block for enhanced self-damping and reduced abrasion.

e. Rounded ending improves the corona voltage.

f. Excellent aluminum alloy material, improves the mechanical and anti-corrosion function for a greatly extended service life.

Purpose

Supporting OPGW cable from tower installations.

Our company provides product installation instructions. For more details, please see the

| Model | For cable diameter (mm) | Length of inner rod (mm) | Length of outer rod (mm) | Clamp strength (kN) |

| 7.6-9.6 | 1600 | 1000 | 70 | |

| 9.7-11.6 | 1800 | 1200 | 70 | |

| 11.7-14.1 | 2000 | 1400 | 70 | |

| 14.2-16.1 | 2200 | 1600 | 70 | |

| 16.2-20.0 | 2600 | 2000 | 100 |

Note: ** represents the cable diameter.

Cautions:

a. Select the suspension clamp according to OPGW cable diameter and other parameters.

b. Configuration: 1 set/ straight line tower.

c. The lay direction of the inner rod is opposite of the lay direction of the OPGW outer wire. The lay direction of OPGW outer wire is right. If left, it should be specified in the order contract.

d. According to the mounting point on the tower, select the appropriate link fittings. (such as the U-screws, U-shackle, UB clevis, etc.)

e. Clamp strength: 70kN, 100kN, 120kN etc.