The KJ421 hydraulic tunneling drilling rig is qualified for the drilling of tunnels whose section falls in the range of 16-68 square meters. It is capable of drilling blast holes and rock bolting in a vertical, inclined and horizontal orientations.

Features - The drill rig is fitted with a flexible boom in two symmetric rectangular coordinates, without any operation blind spots. 360° rotation and self-leveling beam make drill positioning extremely easy. It can also be used for the drilling of lateral cross-cut and rock bolting.

- The drilling rig provides a good view for the operator; balanced layout and the articulated chassis of four-wheel drive ensure the flexible, fast and safe driving in the narrow tunnel.

- The stepped piston is used for the high-frequency impacting rock drill and this can improve the transmission efficiency of impact and drilling speed and reduce the consumption of drilling tools.

- Considerable space and automatic functions enable the driver to concentrate on drilling in a safe, fast and accurate manner;

- All the relevant parts are protected and maintenance is easy.

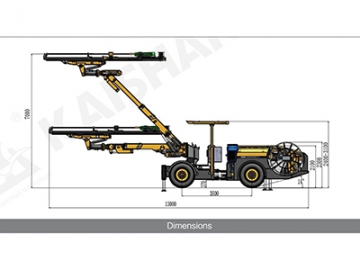

- Dimension

- Turning Radius

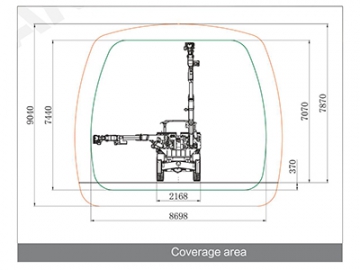

- Coverage area

Technical Parameters

1. Dimensions and weight | Length | 13000mm |

| Width | 2200mm |

| Height | 2400/3100mm |

| Weight | About 22000kg |

| Tramming speed on flat ground | 10km/h |

| Maximum climbing capacity | 25%(14°) |

2. Air& water system | Air compressor | 1×JN11 | Oil consumption of lubrication | 2×180-250 g/h |

| Capacity of air compressor | 1.55m³/min |

| Pressure | 8 bar | Water pump | 1×CR15 |

| Device of shank lubrication | Electronic pulse lubrication pump | Power | 11kW |

| Air consumption of lubrication | 2×0.3m³/min | Capacity of water pump | 12m³/h |

3. Chassis | Diesel engine | Cummins QSB3.9-C125

/93kW/2200rpm | Travelling braking | Wet bridge brake |

| Exhaust purification | Exhaust catalyst | Parking braking | Mechanical brake |

| Drive system | Hydraulic torque converter gearbox | Fuel tank | 120L |

4. Safety protection | Noise level | <100dB(A) |

| Lifting safety roof | Meet the requirements of FOPS and ROPS |

5. Drilling system | Rock drill | 2×HC95LM |

| Impact power | 21kW |

| Impact flow | 100-120L/min |

| Impact pressure | 180-200bar |

| Impact Frequency | 54-62Hz |

| Torque | 764Nm |

| Beam rotation | 360° |

| Feed extension | 1600mm |

| Model of drill boom | K40 |

| Form of drill boom | Self-leveling |

| Boom extension | 1800mm |

6. Electric hydraulic power unit | Motor | 2×75kW Three-phase motor |

| Impact/Feed/Positioning | Axial variable displacement piston pump |

| Rotation | Gear pump |

| Filter fineness | 10 μ |

| Hydraulic oil tank | 400L |

| Hydraulic cooler | Water cooler |

| Working voltage | 380V |

| Frequency | 50Hz |

| Starting method | Star-triangle |

| Cable reel | 1×CRC1016 |

| length of reel cabling | 100m |