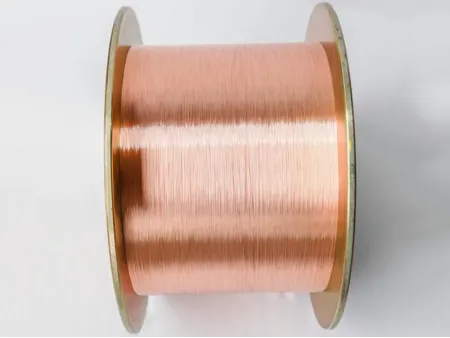

Copper Magnesium Alloy Wire (CuMg)

Magnesium content ranging from 0.10% to 0.4%

Copper Alloy Conductor

Copper magnesium alloy wire combines high strength with excellent resistance to bending, providing an ideal solution for various demanding applications. We produce this alloy with magnesium content ranging from 0.10% to 0.4% using a refined smelting process. Afterward, the alloy undergoes drawing, annealing, electroplating, and stranding to meet the required specifications. Available in single wire, stranded wire, multi-strand ropes, and parallel multi-wire configurations, the wire diameter typically ranges from 0.03mm to 8.0mm.

- 0.2351mm→0.0805mm (13 drawing dies)

- 0.641mm→0.164mm (19 drawing dies)

- 0.4610mm→0.127mm (20 drawing dies)

| Copper Alloy | Magnesium Content | Melting Point | % IACS | Properties |

| CuMg 0.2 | Mg 0.14-0.26% | 1078℃ | 75 | Copper magnesium alloy (CuMg) provides high tensile strength and maintains reliable electrical conductivity at 20°C in a soft condition. |

| Wire Drawing | Wire Stranding/Multi-Wire Processing | Wire Plating |

| Can be drawn down to 0.02mm | Stranded Wires,Parallel Multi Wires | Bare Wire,Tin Plating,Silver Plating,Nickel Plating,Copper Plating Enameling: Polyurethane QA(UEW),155/180℃ Polyester QZ(PEW),130/155℃ Polyesterimide QZY(EIW),180℃ Polyamideimide QXY(AIW),200/220℃ |

| Wire Type | Magnesium Content | Tensile Strength (Mpa) | Single Wire Diameter (mm) | DC Resistance at 20℃ | Lay (mm) | Size (mm) |

| 7/0.154 CuMg 0.2 | Mg(0.2±0.06)% | >700 | 0.152-0.160 | 160-170 | 10.0-14.0 | 0.43-0.49 |

| Construction | Number of Wires | Coating Material | Thickness | Elongation |

| 0.90mm | 1 | Silver | 7μm | Min. 10% |

| 1.30mm | 1 | Silver | 17μm | Min. 22% |

| 1.80mm | 1 | Tin | 3μm | Min. 15% |

- Central control wiring harnesses

- Communication wiring harnesses

- Aerospace wiring systems

- ABS brake system wiring

- Wiring for industrial robots

Compared to traditional copper wire, copper magnesium alloy wire offers superior strength and enhanced flexibility. Although the alloy has slightly higher resistance, the impact on signal transmission is minimal, ensuring reliability in applications that require durability and flexibility.