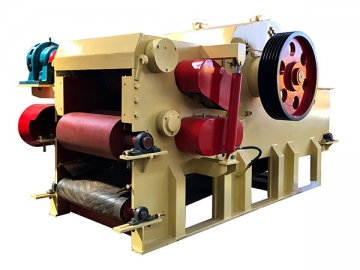

Drum Chipper

Production Rate: 10~62

1. Drum chipper of this series can handle a variety of woody materials, including twigs and branches, face and back veneer, waste solid wood panels, bamboos, and cotton stalks. It is an important part of wood pelleting operation.

2. Consists of a base, roller cutter assembly, upper and lower feed rollers, conveying equipment, hydraulic system, and electrical control. Rigid structure, reliable wood chipping performance, and easy operation are three major traits of our drum chipper.

3. The upper feed roller is connected to the base via a pivot shaft. As woody biomass enters or exits the wood chipper, the upper roller swings up and down to quickly adapt itself to the size of wood materials being chipped. The roller is hydraulically powered to adjust its height. It is a lightweight structure with coarse teeth around its surface to press down on the material and feeds it into the cutter at a constant speed. Chipped wood falls through the screen and exits from the bottom while oversize wood is sent back for rework.

4. The hydraulic system uses an oil pump to supply oil to a small hydraulic cylinder. The cylinder then pushes open the top cover for quick fly cutter replacement. The oil pump also sends oil to a large hydraulic cylinder to raise the upper feed roller so operators can adjust the gap between the upper fly cutter and the bottom knife as well as change in and out the comb plate.

| Parameters | Model | ||||||

| Dia . of roller cutter | mm | 650 | 800 | 800 | 800 | 1000 | 1000 |

| Inlet size(H x W) | 180x500 | 225x 680 | 240 x 750 | 240x1050 | 330x750 | 330x850 | |

| No. of fly cutters | pcs | 2/3 | 2/3 | 2 | 3x2 | 2 | 2x2 |

| Rotating speed | rpm | 590 | 650 | 650 | 650 | 550 | 550 |

| Feeding speed | m/min | 37 | 38 | 38 | 39 | 37 | 37 |

| Max dia . of wood material | mm | 120 | 160 | 160 | For chipping solid wood panels | 170 | 185 |

| Capacity | m3/h | 10 | 22 | 38 | 30 | 55 | 62 |

| Productivity | |||||||

| Chip size | mm | 30 | 30 | 30 | 20 | 33 | 33 |

| Main motor power | kW | 55 | 110 | 132 | 160 | 160 | 185 |

| Feeding roller motor power | kW | 3x2 | 4x2 | 4x2 | 5.5x2 | 7.5x2 | 7.5x2 |

| Oil pump power | kW | Hand pump | 0.55 | 0.55 | 0.55 | 2.2 | 2.2 |