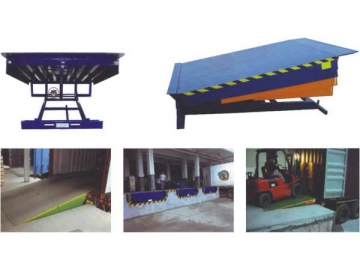

The fixed hydraulic dock leveler is a special auxiliary device used for quick loading and unloading of goods. With adjustable height, it serves as a bridge between truck and dock of the storehouse. Forklift and other handling vehicles can enter the interior of the truck directly through this device to conduct batch loading and unloading of goods, which is highly efficient.

Specifications of 6 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ6-0.55 | 6000 | 2×2 | 0.4 | 0.3 | 0.25 | 2.08 | 2.04 | 0.6 | 0.75 | 1200 |

Specifications of 6 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ6-0.7 | 6000 | 2.5×2 | 0.4 | 0.4 | 0.3 | 2.58 | 2.04 | 0.6 | 1.5 | 1300 |

Specifications of 8 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ8-0.55 | 8000 | 2×2 | 0.4 | 0.3 | 0.25 | 2.08 | 2.04 | 0.6 | 1.5 | 1250 |

Specifications of 8 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ8-0.7 | 8000 | 2.5×2 | 0.4 | 0.4 | 0.3 | 2.58 | 2.04 | 0.6 | 1.5 | 1360 |

Specifications of 10 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ10-0.55 | 10000 | 2×2 | 0.4 | 0.3 | 0.25 | 2.08 | 2.04 | 0.6 | 1.5 | 1300 |

Specifications of 10 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ10-0.7 | 10000 | 2.5×2 | 0.4 | 0.4 | 0.3 | 2.58 | 2.04 | 0.6 | 1.5 | 1400 |

Specifications of 15 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ15-0.7 | 15000 | 2.5×2 | 0.4 | 0.4 | 0.3 | 2.58 | 2.04 | 0.6 | 1.5 | 1900 |

Specifications of 20 Ton Fixed Hydraulic Dock Leveler | Model | Rated load kg | Platform size m | Thickness if the lip plate m | Slope range m | Pit size m | Power kw | Overall weight kg |

| Highest | Lowest | L | W | H |

| DCQ20-0.7 | 20000 | 3×2.5 | 0.4 | 0.4 | 0.3 | 3.08 | 2.54 | 0.6 | 2.2 | 2800 |

Fully hydraulic driven, the fixed hydraulic dock leveler is easy to operate and runs stably. The adoption of imported sealing element ensures excellent seal performance of the hydraulic system. The high-strength U shape beam design enables this product to support heavy load for long hours without deformation. The non-slip checkered steel plate makes the platform has good anti-slip performance. To ensure the safety of operators entering the dock leveler for maintenance, the dock leveler is equipped with supporting bar.

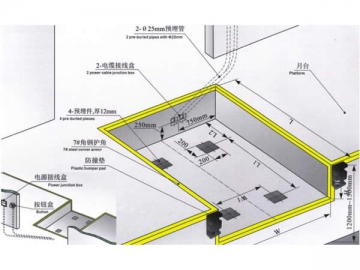

Requirements of the Foundation Pit

1. The reserved foundation pit must be straight and square and the allowable error of the diagonal is less than 10mm.

2. Power junction box meeting safety standards must be prepared in advance in the outlet position of the electric tube. The size must accord strictly with that shown in the installation diagram of foundation pit provided by us.

3. The user should provide power to the electric cabinet of the platform and the electric cabinet is generally 1,200mm away from the platform surface.

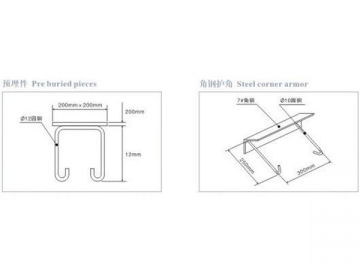

4. Steady anti-collision angle iron should be prepared at the border of the pit and it must be firmly connected with the steel mesh by barbed iron.

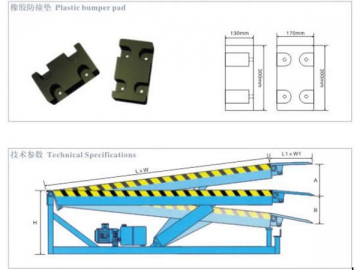

5. Both sides of the front part of the pit should be solid and flat to install plastic bumper pads.

6. The back end of the pit should be a little higher than the front end (about 10 to 15mm), preventing stagnant water caused by cleaning or rain.

7. Electric pipelines meeting local safety standards should be buried under the concrete. Diameter of the wire tube is 20mm to 25mm.

8. There are internal wall type and external wall type of the installation of the regulation board. Please arrange the tube according to the specific situation.

9. Concrete should be deposited around the foundation pit. C15-C30 concrete are often adopted. Thickness of the bottom concrete is no less than 40cm and thickness of both sides is equal or greater than 25cm.

10. Shape and size of the foundation pit doesn't apply to all customers and these diagrams are just for reference.

As a China-based fixed hydraulic dock leveler manufacturer, Secure offers a broad range of products that includes mobile yard ramp, scissor aerial work platform, hanging rail BMU cradle, and suspended platform hoist, among others.