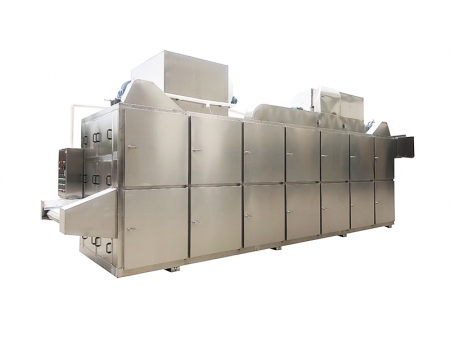

Drying Machine

- Drum dryer for shipment

- Semi-finished drum dryer

- Finished drum dryer

Applications

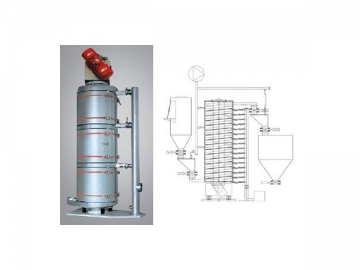

1. This drum dryer, as a member of the biomass fuel equipment family, is primarily used for drying granular and powdered material such as wood chips and wood powder. The rotary dryer has been applied to biomass fuel, environmental protection and other industries.

2. The compound fertilizer drum drying machine is used to dry materials with a certain moisture content. It is primarily used in chemical, chemical fertilizer and building industries for drying blast furnace slag, clay, limestone pulverized coal and quartz stone.

3. In metallic ore dressing plants, the drum dryer can be used to dry metal concentrates, leaching residues and gangue.

4. The multi-purpose dryer is also suitable for iron and steel plants to dry clean coal, fluorite, and oxidized iron scale.

5. Our drum dryer can be used to dry nearly any material that is resistant to high temperatures, has no chemical reactions, and produces no harmful gases during the drying process.

Features

1. This drum dryer is an industrial dryer whose working temperature is lower than 400ºC. It spreads the material on the drum surface in order to ensure a more efficient drying. Customers can request either a single drum dryer or a triple drum dryer.

2. The production capacity of the multi-purpose dryer is also customizable.

| Type | Size (drum diameter × drum length) | Inner diameter (mm) | Length (mm) | Power (kW) | Production capacity ( t/h) | Maximum intake air temperature (°C) |

| 1.8×9 | 1800 | 9000 | 2.2×2 | 1-1.5 | 700 | |

| 2.0×9 | 2000 | 9000 | 2.2×2 | 1.5-2 | ||

| 2.3×9 | 2500 | 9000 | 2.2×2 | 3-4 | ||

| 3.0×9 | 3000 | 9000 | 3.0×2 | 4-5 | ||

| 1.5×15 | 1500 | 15000 | 3.0×4 | 1-2 | ||

| 2.0×15 | 2000 | 15000 | 3.0×4 | 2-3 | ||

| 2.3×18 | 2300 | 18000 | 4.0×4 | 3-5 | ||

| 2.5×23 | 2500 | 23000 | 5.5×4 | 5-8 | ||

| 3.0×23 | 3000 | 23000 | 7.5×4 | 6-9 |

Related Names

Multi-Purpose Pellet Dryer | Industrial Dryer | Drum Dryer | Biomass Fuel Equipment | Wood Rotary Dryer