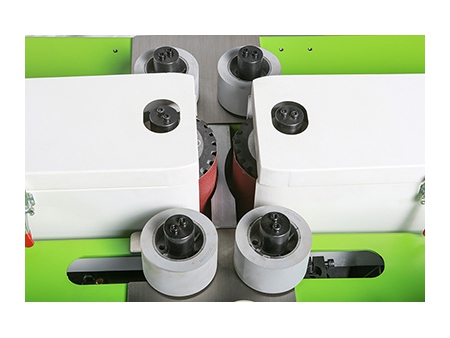

Double Door Flap Valve (left & right door)

A flap gate is a flow control device that functions as a check valve. It opens and closes automatically to release the water and prevent reverse flow conditions under gravity and the pressure different between inside and outside the door. Featuring an excellent water shutoff capability, strong corrosion resistance and easy installation, the double door flap gate is widely applied in drainage pipes and wastewater treatment projects.

Specification

Flap gates of diverse specifications are available upon request

How It Works

The double-door flap gate works to release water out of the pipeline and prevent reverse flow conditions. The door is comprised of the left and the right parts, both of which open and close under the pressure difference between inside and outside the door.

Advantages of Flap Gate

1. Counterweight is unnecessary

2. When the valve opens, the lower door opens first, then the upper. With a large open angle, the valve allows for less energy loss

3. Impact for the valve seat is reduced as the valve closes its upper door first when the valve closes

Installation Precautions

1. Before installing, weld the seat with embedded reinforcement and pour concrete on it

2. For optimum performance, operators can inject water into the valve's sealed cavity or release a certain amount of water from the valve to change the doors' weight proportion.

3. When installing several non-return valves at the same time, please ensure that each valve seat exactly matches each door.

4. Before installing the flap valve, please check whether the bolt connectors are loose during delivery and fix the loose parts

5. Ensure that the valve seat and the door are on the same plane

6. In case of door deformation, the valve seat and the door should be installed as a whole rather than being mounted separately.

7. Before pouring the concrete for the second time, find the right installation location, and then weld the bolts with embedded reinforcement.

8. A frame plate is mounted on the flap gate during the production to make sure the seat and door fit tightly. Therefore, remember to remove the frame plate from the drainage system so that the valve can open and close smoothly.

9. The mortar flowing into the seat, door, and baffle gap during the concrete pouring process should be removed completely to make sure the valve moves easily.

You may also find products like:

Flow Control Device, Check Valve for Flood Prevention, Waste Backwater Valve, Drainage Pipe Gate