BFS Vacuum Decay Leak Testing Machine

Container Closure Integrity Testing (CCIT)

- Applicable container: BFS plastic ampoules (clean and dry)

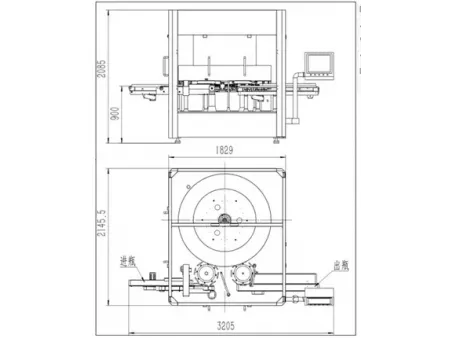

- Max. size of container: 135×900mm

- Machine dimensions (L×W×H): 3000×1900×2200mm

- Power supply: 380V 3 phase 50Hz

- Designed for non-destructive integrity testing of BFS plastic ampoule containers filled with pharmaceutical products

- Supports 100% online and offline inspection, even under high-speed production conditions

- Leak detection is performed inside a sealed test chamber with a pressure differential

- Determines container integrity by measuring achieved pressure levels and monitoring pressure changes during the test cycle

- Capable of identifying micro leaks, seal failures, and cracks that may compromise sterility

- Requires test containers to be clean and dry for accurate results

- Suitable for installation in Class C and D cleanroom environments during less critical aseptic processing stages

- All validation and qualification processes are fully aligned with current Good Manufacturing Practice (GMP) guidelines.

- Materials and construction methods meet the hygiene and quality standards required in pharmaceutical production environments.

- The testing system features a polycarbonate safety shield to prevent injuries from accidental contact or compression.

- Its clean design minimizes the risk of contamination by eliminating hard-to-clean corners or areas where residue might accumulate.

- A clear separation is maintained between the technical components and the product-handling zone to ensure controlled processing conditions.

- Automatic feeding and unloading streamline the handling of BFS containers during the testing process

- High sensitivity enables the detection of even the slightest leaks with precision

- Delivers fast, reliable, and repeatable test results for consistent quality assurance

- Utilizes a non-invasive, non-destructive method that preserves product integrity

- Enhanced HMI offers intuitive controls and smooth system interaction

- Built-in self-diagnostic capabilities improve operational reliability

- Hygienic design with no hidden corners simplifies cleaning procedures

- All moving parts are easily accessible, making routine maintenance more efficient

- Tracks and stores historical production, testing, event, and alarm data for traceability

- Real-time display of leak testing curves on the HMI helps operators monitor performance instantly

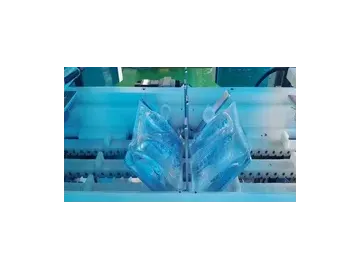

Vacuum-based leak testing is carried out using 30 chambers, each designed to perform non-destructive integrity testing on sealed pharmaceutical containers. Once capped, the containers are transferred via a conveyor, then spaced apart by a screw feed system and positioned beneath the inspection units. Each chamber lowers to enclose the bottle in a sealed, fixed-volume cavity.

Inside the chamber, the testing system measures vacuum levels and monitors any pressure changes over time. A pressure drop that exceeds the allowed threshold indicates a potential leak, such BFS containers are automatically removed from the line. Accepted products continue smoothly to the next stage.

Tailored for high-throughput production lines, this leak testing solution can be integrated directly into existing setups, helping maintain both speed and quality without compromising container integrity.