Can Body Upender (Can Up-Righter)

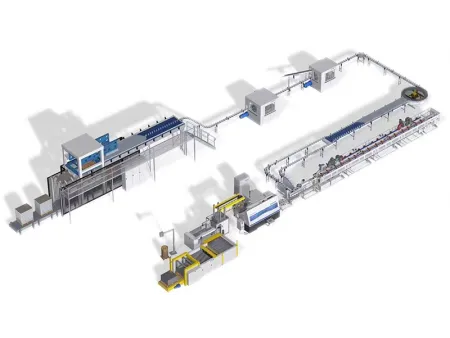

The can body upender automatically turns horizontally conveyed tinplate can bodies into an upright position, so they can enter downstream automation steps such as conveying, inspection, palletizing or filling in a stable and controlled way.

The V-type can upender is widely used on tinplate easy-open can production lines, providing a stable and efficient way to turn can bodies from a horizontal position to an upright orientation for downstream processing.

| Belt width | 50 to 80 mm |

| Belt material | PU belt |

| Frame | 304 stainless steel, powder coated carbon steel or aluminium |

| Motor | 1.5 kW × 2 (Liming, Taiwan) |

| Applicable can types | Various tinplate easy-open can bodies |

| Upending connection options | Multiple layouts, including straight 90-degree discharge and 90-degree corner transfer |

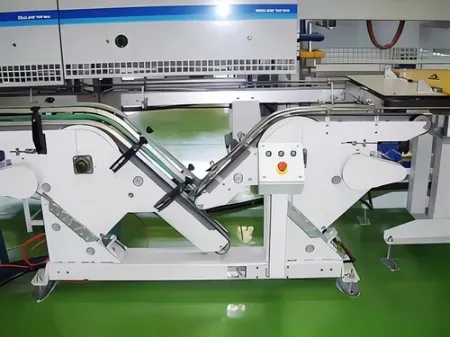

Compared with the V-type can upender, the magnetic can body upender is designed for higher-speed production lines where fast, stable can upending is required.

- Belt width: 50 to 80 mm

- Belt material: PU belt

- Frame: 304 stainless steel, powder coated carbon steel or aluminium

- Motor: 1.5 kW × 2 (Liming, Taiwan)

This newly designed rotary can body upender has one key advantage: it can eliminate the need for a separate U-turn conveyor in the next stage, helping you simplify the production line layout and reduce equipment and investment costs.

- Belt width: 50 to 80 mm

- Belt material: PU belt

- Frame: 304 stainless steel, powder coated carbon steel or aluminium

- Motor: 1.5 kW × 2 (Liming, Taiwan)

- Applicable can types: All tinplate cans

All other parameters can be tailored to match your specific line layout and production requirements.