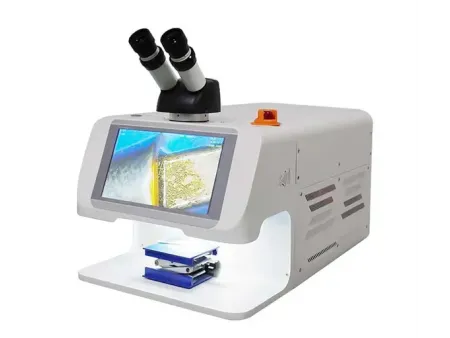

Jewelry Laser Spot Welding Machine

- Laser type YAG laser

- Pulse width 0.1-5ms

- Laser spot size 0.1-3mm

- Machine weight 35kg

The jewelry laser spot welding machine utilizes 1064nm wavelength YAG laser technology, offering a single pulse energy of up to 90J and an adjustable spot size from 0.1-3.0mm. It supports non-destructive welding of highly reflective metals such as gold, silver, and platinum, with a heat-affected zone (HAZ) of less than 0.2mm, ensuring no oxidation or deformation on the jewelry surface. Integrating a high-definition CCD microscope observation system and an electronic light filter device, operators can clearly view welding details without wearing protective goggles. Coupled with an ergonomic design, it can complete over 500 precise welding tasks per day, boosting efficiency by 5 times compared to traditional methods. It is an innovative tool for jewelry repair, setting, and micro-engraving.

- Precious metals: Gold (24K/18K), silver, platinum, titanium alloy, K gold.

- Highly reflective materials: Copper, brass, nickel-plated/galvanized metals.

- Precision parts: Dental prosthetics, watch hairsprings, battery nickel strips, jewelry chains.

- Dissimilar metal combinations: Gold-silver, copper-titanium, stainless steel-platinum.

- Laser welding for ring repair

- Laser welding for jewelry repair

- Jewelry laser welding

- Finger ring laser welding

- Metal jewelry laser welding

- Metal jewelry laser welding

- Eyeglass frame laser welding

- Metal jewelry laser welding

- Technical Data

- Configuration

- Laser type YAG laser

- Laser power 60W, 100W, 150W, 200W

- Machine weight 35kg, 37kg, 39kg

- Pulse width 0.1-5ms

- Frequency 0-10Hz

- Laser spot size 0.1-3mm

- Operation system LED touch screen

- Touch screen size 10.8''

- Monitoring system microscope CCD

- Cooling method water cooling

- Power supply 220V/50Hz, 110V/60Hz

- Machine dimensions 570×290×290mm

- Machine weight 35kg

- Package size 730×430×570mm

- Package weight 49kg

YAG laser & xenon lamp

Employs a 1064nm wavelength laser with single pulse energy up to 50-110J, providing concentrated photon energy and a heat-affected zone of only 0.2-0.5mm, ideal for cold processing highly reflective metals like gold, silver, and platinum, preventing oxidation and deformation. The xenon lamp's trigger voltage is precisely controlled, with discharge energy fluctuation <3%, ensuring welding consistency and an electro-optical conversion efficiency ≥30%.

Touch screen

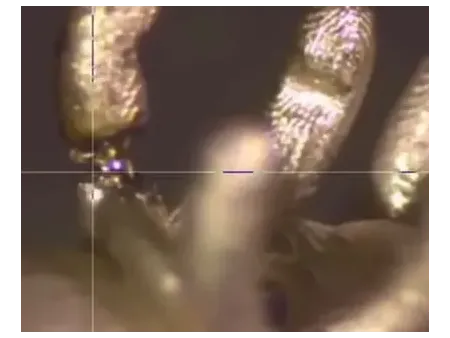

Features a high-definition LED touch screen that supports Chinese-English switching and real-time display of welding parameters for intuitive operation. It includes a built-in crosshair microscope with magnification ≥20x, allowing clear positioning of 0.1mm-level welds and preventing misoperation.

Automatic shading system

Automatically activates the shading hood during welding, with light transmittance <0.1%, preventing laser scattering from harming the eyes and complying with Class 1 safety standards.

Emergency stop button

When the emergency stop button is triggered, the laser output is cut off within <0.1 seconds, ensuring operational safety.

- Welding Wire

- Industrial-grade external water chiller

- Mini welding host unit

- HD microscope

- Foot pedal switch

- Power cord

- Hex wrench set

- Spp10 plug

- A4 black laser paper (for calibration)

- M10 water pipe

- M6 argon pipe

- Mini lifting platform (100×100×150mm)

- Hand rest pad

- Xenon lamp tube

- Protective lenses

- Equipment warranty certificate

- Shipping accessories list

- Product catalog

Can this precision welding machine weld plated precious metals (e.g., gold/silver plated jewelry)?

What is the water change frequency for the built-in water tank of this Metal Craft Welding Machine?

Can the jewelry welder work continuously for long periods, or does it require breaks?

What after-sales service and warranty policies are provided after purchasing the metal welder?

What should be noted when it comes to jewelry soldering?

Why do you need a laser welder to weld your jewelry?

Can you provide welding parameters for welding platinum, gold, and silver with the welding equipment?

For 18K Gold Craft Welding:

- Laser Current (Power): 15%

- Pulse Width: 1.8 ms

- Spot Size: 0.3 mm For Pure Gold Craft Welding

- Laser Current: 46%

- Pulse Width: 5.2 ms

- Spot Size: 0.5 mm

- Note: It is recommended to blacken the surface of the weld spot before welding (e.g., using a laser absorber or black marker pen) to enhance laser absorption, preventing unstable welding or energy waste caused by laser reflection.