One-to-Two/One-to-Four Separate Hopper Loader

Request a Quote

SAL-UG122/124

Multi-station hopper loader for conveying plastic granules to hopper or processing machine

Designed to meet the needs of complex industrial environments, this separate hopper loader enhances the logistical efficiency of plastic material handling. Suitable for a variety of configurations, it ensures a streamlined process in distributing materials to multiple destinations or machines, effectively supporting high or long-distance conveying requirements.

Features

- Features an LED display for easy operation.

- Compatible with either two or four hoppers, making it suitable for high or long-distance conveying.

- Includes a dual-stage cyclone dust collector and a large dust tank for quick and easy maintenance.

- All models are equipped with vacuum release valves to protect the blower and extend the equipment's lifespan.

- Models with 5HP or more come standard with an automatic spray cleaning system, reducing the frequency of manual cleaning.

- Standard 485 communication interface facilitates remote monitoring for automated production setups.

Diagram

Applications

This separate hopper loader is ideal for use with multiple dehumidifying dryers for transporting various plastic materials. It also supports efficient material transportation to different molding machines or hoppers, whether operating in a one-to-two or one-to-four configuration, offering significant cost savings.

Specifications

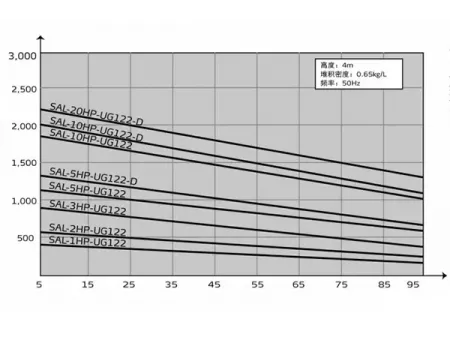

| SAL-UG122 | ||||||||

| Model | Motor power (kW) | Phase | Dimensions (mm) H×W×D | Weight (kg) | Hopper receiver | Conveying pipe diameter (inch) | Vacuum pipe diameter (inch) | Conveying capacity (kg/hr) |

| 0.75 | 3φ | 990×350×488 | 52 | 2×SHR-3U-S | 1.5 | 2 | 400 | |

| 1.5 | 3φ | 990×350×488 | 56 | 2×SHR-6U-S | 1.5 | 2 | 550 | |

| 1.85 | 3φ | 990×350×488 | 60 | 2×SHR-12U-S | 1.5 | 2 | 800 | |

| 3.75 | 3φ | 1410×720×570 | 175 | 2×SHR-12U-S | 1.5 | 2 | 1200 | |

| 3 | 1410×720×570 | 180 | 2×SHR-12U-S | 1350 | ||||

| 7.5 | 3φ | 2020×840×820 | 185 | 2×SHR-24U/36U-S | 2 | 2.5 | 1700/1800 | |

| 2020×980×820 | 192 | 2×SHR-24U/36U-S | 1900/2000 | |||||

| 11 | 3φ | 2145×1055×1000 | 246 | 2×SHR-48U/96U-S | 2.5 | 3 | 2200/2300 | |

| Notes: 1) Test conditions of conveying capacity: Plastic material of 0.65kg/L in bulk density and 3-5mm in diameter Vertical conveying height: 4m Horizontal conveying distance: 5m 2) Power: 3Φ, 400VAC, 50Hz | We reserve the right to change specifications without prior notice. | |||||||

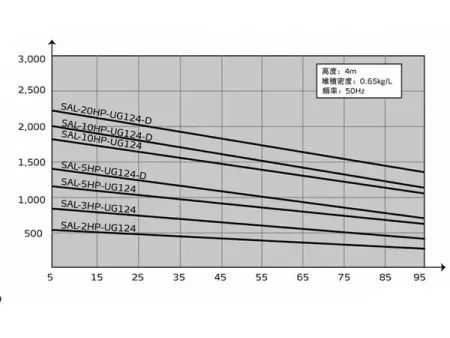

| SAL-UG124 | ||||||||

| Model | Motor power (kW) | Phase | Dimensions (mm) H×W×D | Weight (kg) | Hopper receiver | Conveying pipe diameter (inch) | Vacuum pipe diameter (inch) | Conveying capacity (kg/hr) |

| 1.5 | 3φ | 990×350×533 | 60 | 4×SHR-3U-S | 1.5 | 2 | 550 | |

| 1.85 | 65 | 4×SHR-6U-S | 800 | |||||

| 3.75 | 3φ | 1410×825×585 | 175 | 4×SHR-12U-S | 1.5 | 2 | 1200 | |

| 3 | 1410×825×585 | 180 | 4×SHR-12U-S | 1350 | ||||

| 7.5 | 3φ | 2020×930×855 | 185 | 4×SHR-24U/36U-S | 2 | 2.5 | 1700/180C | |

| 2020×1065×855 | 192 | 4×SHR-24U/36U-S | 1900/2000 | |||||

| 11 | 3φ | 2145×1150×1000 | 246 | 4×SHR-48U/96U-S | 2.5 | 3 | 2200/2300 | |

| Notes: 1) Test conditions of conveying capacity: Plastic material of 0.65kg/L in bulk density and 3-5mm in diameter Vertical conveying height: 4m Horizontal conveying distance: 5m 2) Power: 3Φ, 400VAC, 50Hz | We reserve the right to change specifications without prior notice. | |||||||