High Mast LED Light

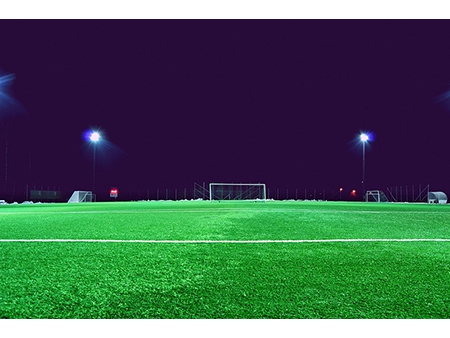

High mast LED lights are used for lighting systems that need to cover a very large area, such as in stadiums, billboards and large intersections. Our high mast LED lights are highly effective and provide wide lighting range.

- BRHPL-A1 High Mast Pole

- BRHPL-A1 High Mast Pole

- BRHPL-A2 High Mast Pole

- BRHPL-A2 High Mast Pole

| 1. All of our materials are purchased from trusted sources. |

| 2. A mill certificate issued by the mill factory with stamp and signature must be provided before unloading the material in our factory, otherwise we will refuse delivery. |

| 3. Before producing, all the material must pass the chemical and physical analysis to make sure that they have met the requested strength components. |

Testing Including

1. Material Testing

2. Shape Testing

3. Testing after Galvanization

4. Tensile Testing

5. Fittings Checking

We manufacture of high mast lighting poles with heights from 12-50m

| Height | From 12M to 50M |

| Applications | Airport, seaport, plaza, stadium, highway station, intersections ,etc |

| Shape | Round, Multi-pyramidal, Column form, polygonal or conical |

| Material | Q345B/A572,minimum yield strength>=345n/mm2 Q235B/A36,minimum yield strength>=235n/mm2 |

| Torrance of dimension | - 2% |

| Lighting Source | 400 W- 5000 W high pressure sodium flood light, light extension :up to 30 m ² /100W-250W LED |

| Light plate | Various figure of selection ,material with hot dip galvanization steel frame |

| Lifting system | Lifter fixed in the inner of the pole with lifting speed of 3~5 meter per minute Equipped e; ant ferromagnetism brake and break – proof device, manual operation applied under power cut |

| Electric appliance control device | Electric appliance box to be the hold of the pole, lifting operation can be 5 meters away from the pole through a wire. Time control and light control can be equipped to realize full-load lighting mode and part lighting mode |

| Surface treatment | Hot dip galvanization, ASTM A 123, color polyester power or any other standard by client required. |

| Joint of Poles | insert mode, inner flange mode, and face to face joint mode. |

| Design of pole | Can withstand an earthquake up to an 8 grade |

| Wind Speed | 160 Km/Hour |

| Welding | Internal and external double welding |

| Thickness | 6 mm to 30 mm |

| Production Process | Raw material test → Cutting → Molding or bending → Welding (longitudinal ) → Dimension verify → Flangewelding → Hole drilling → Calibration → Deburr → Galvanization or powder coating, Painting → Recalibration → Thread → Packaging |

Lifting system For High Mast Lamp

Latch barrel with inner mounting bracket locker is mounted to an underside of the mast-top pulley assembly. Furthermore, all steel cables are not exposed and are more effectively protected.

A latching mechanism fitted on steering arms is able to release strain on steel cables when in the operation position. The process of latching on and off is stable and without vibration. The bumper is designed on the luminary mounting bracket for avoiding direct damage between mast-top assembly and the raising luminary mounting bracket.

The leveling device for luminary support bracket is easy to operate and convenient to adjust the level.

| Plaza High Mast Lighting Airport High Mast Lighting Highway High Mast Lighting Storage-yard High Mast Lighting Industrial-plant High Mast Lighting | Park High Mast Lighting Dock High Mast Lighting Stadiums High Mast Lighting Overpass High Mast Lighting Toll-station High Mast Lighting |

Producing Capacity

Within 30 days for 30 high mast lighting poles on receipt of payment

Packing

Bulb wrappings for high mast lighting poles, individual cartons for lamps and controlling equipments, etc. A 40' HP loads 7-20M/ 6-25M/ 5-30M/ 4-35M high mast lights.