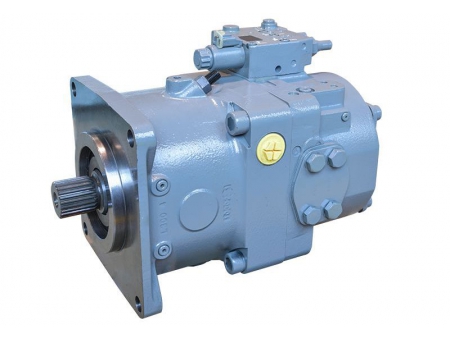

O-Ring Loaded Seal, L Shape

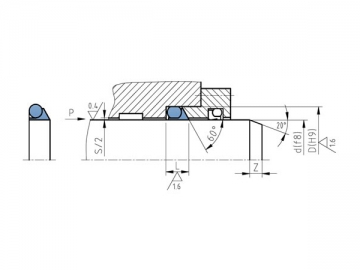

The L-shaped o-ring loaded seal is made up of an o-ring, measuring up to GB/T3452.1-2005 standards, and a PTFE filled seal that is of an L shape. This single-acting rod seal is suitable for use with the guide ring and piston ring, and fits around a reciprocating rod or piston in a high-pressure hydraulic system where pressure is applied from one side only. For a rod with a diameter less than 100mm, we suggest going with an open-groove seal design.

Operating conditions

Operating pressure: 0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Rod diameter d(f8) | Groove diameter D(H9) | Groove width b 0.2 | O-ring diameter d2 | Fillet R | Round r | Radial clearance S≤ | Chamfer Z≥ |

| 8~17 | d 5.0 | 4.2 | 2.65 | 0.2~0.3 | 0.1~0.3 | 0.2 | 2 |

| 18~39 | d 6.6 | 5.2 | 3.55 | 0.3~0.5 | 0.3 | 3 | |

| 40~108 | d 9.6 | 7.8 | 5.30 | 0.4~0.8 | 0.4 | 5 | |

| 109~900 | d 12.5 | 9.8 | 7.00 | 0.8~1.2 | 0.4 | 7 |

Operating conditions

Operating pressure: 0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

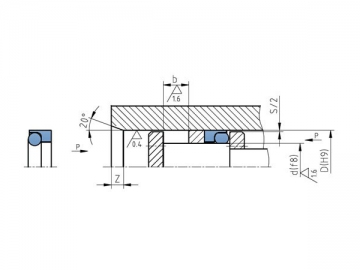

O-ring loaded seal installation diagram

Related Specs

| Rod diameter d(f8) | Groove diameter D(H9) | Groove width b 0.2 | O-ring diameter d2 | Fillet R | Round r | Radial clearance S≤ | Chamfer Z≥ |

| 10~22 | d 4.5 | 4.0 | 2.4 | 0.2~0.3 | 0.1~0.3 | 0.3 | 2 |

| 23~160 | d 5.7 | 4.8 | 3.1 | 0.3~0.5 | 0.3~0.4 | 3 | |

| 22~50 | d 6.5 | 5.2 | 3.5 | 0.3~0.4 | 0.3 | 3 | |

| 40~290 | d 10.4 | 8.2 | 5.7 | 0.3~0.5 | 0.4 | 5 | |

| 155~1000 | d 15.2 | 11.6 | 8.6 | 0.4~0.6 | 0.4 | 7 |

Operating conditions

Operating pressure: 0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

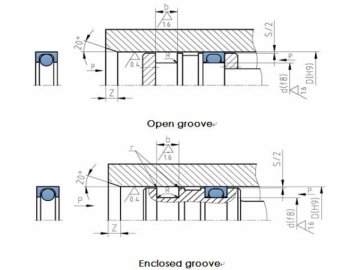

O-ring loaded seal installation diagram

Related Specs

| Cylinder diameter D(H9) | Groove diameter d(f8) | Groove width b 0.2 | O-ring diameter d2 | Fillet R | Round r | Radial clearance S≤ | Chamfer Z≥ |

| 13~23 | D-5.3 | 4.2 | 2.65 | 0.3~0.4 | 0.1~0.3 | 0.3 | 2 |

| 24~49 | D-6.8 | 5.2 | 3.55 | 0.3~0.4 | 0.4 | 3 | |

| 50~121 | D-10.0 | 7.6 | 5.30 | 0.3~0.5 | 0.3~0.4 | 5 | |

| 122~900 | D-13.0 | 9.6 | 7.00 | 0.4~0.6 | 0.4~0.6 | 7 |

Operating conditions

Operating pressure: 0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Cylinder diameter D(H9) | Groove diameter d(f8) | Groove width b 0.2 | O-ring diameter d2 | Fillet R | Round r | Radial clearance S≤ | Chamfer Z≥ |

| 28~165 | D-5.9 | 4.8 | 3.1 | 0.3~0.5 | 0.1~0.3 | 0.3~0.4 | 3 |

| 28~56 | D-6.8 | 5.2 | 3.5 | 0.3~0.4 | 0.3 | 3 | |

| 60~300 | D-10.8 | 8.2 | 5.7 | 0.4~0.5 | 0.3~0.5 | 5 | |

| 170~1000 | D-15.9 | 11.6 | 8.6 | 0.4~0.6 | 0.3~0.6 | 7 |

Operating conditions

Operating pressure: 0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Groove diameter D(H11) | O-ring diameter d2 | Groove width b 0.25 | Groove depth h 0.1 | Fillet R | Round r |

| 15~26 | 2.65 | 4.5 | 2.4 | 0.2~0.4 | 0.1~0.3 |

| 27~50 | 3.55 | 5.6 | 3.2 | 0.4~0.6 | |

| 51~128 | 5.30 | 7.9 | 4.8 | 0.6~0.8 | |

| 129~690 | 7.00 | 10.5 | 6.3 | 0.8~1.2 |

Operating conditions

Working pressure:0~60MPa

Operating temperature: -55~ 2500°C (depending on the kind of o-ring material)

Reciprocating speed: ≤6m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Groove diameter D(H11) | O-ring diameter d2 | Groove width b 0.25 | Groove depth h 0.1 | Fillet R | Round r |

| 17~29 | 2.4 | 4.1 | 2.20 | 0.3 | 0.1~0.3 |

| 31~168 | 3.1 | 4.9 | 2.80 | 0.3~0.4 | |

| 31~59 | 3.5 | 5.6 | 3.20 | 0.3 | |

| 63~303 | 5.7 | 8.4 | 5.10 | 0.3~0.5 | |

| 175~505 | 8.6 | 12.5 | 7.50 | 0.4~0.5 |