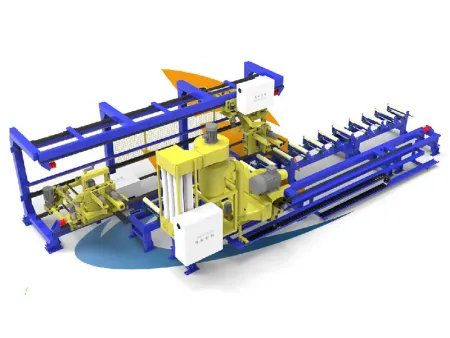

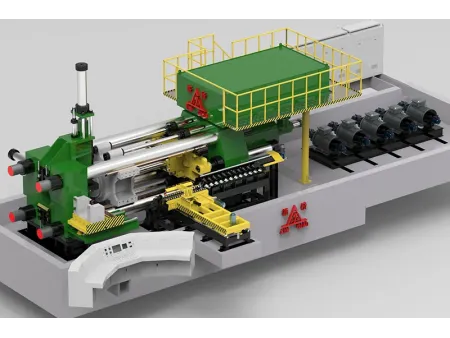

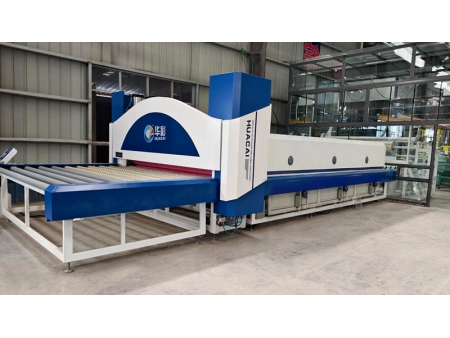

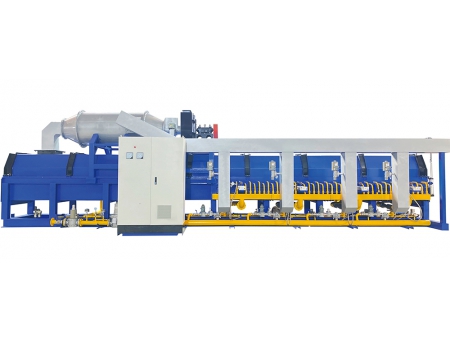

Single Billet Furnace (Aluminum Billet Heating Furnace)

Request a Quote

Aluminum Extrusion Equipment

Log heat furnace for heating single aluminum billet to the desired temperature for extrusion

The single billet jet-type heating furnace integrates thermal, mechanical, and automated control technologies, providing a complete heating solution to the desired temperature for aluminum extrusion. This heating furnace ensures energy efficiency, precise temperature control, and optimal performance for high-quality aluminum extrusion processes.

Specifications

| Power | 18kW |

| Voltage | 380V,50Hz |

| Working Temperature | 450 to 520℃ |

| Temperature Uniformity | ±5℃ |

| Heating Method | Natural gas/LPG |

| Aluminum Billet Diameter | 4" (101mm),6" (152mm),7" (178mm),8" (203mm),10" (254mm),12" (305mm) |

| Heating Energy Consumption | 10-20m³/N (vary depending on billet size) |

Features

- Utilizes liquefied petroleum gas (LPG) or natural gas for enhanced jet heating, combined with hydraulic hot shearing and other advanced technologies. Compared to traditional multi-billet heating furnaces, it saves up to 40% of fuel consumption.

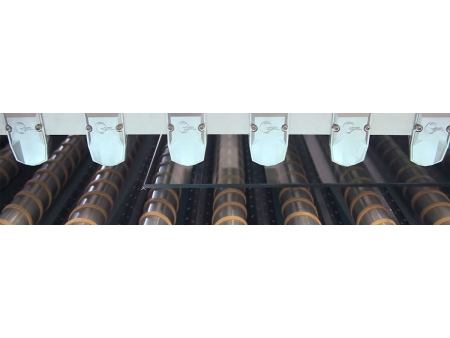

- Employs multi-zone direct-fired jet heating for rapid heating of aluminum billets. Preheats billets using exhaust heat before entering the heat exchanger, which preheats combustion air to lower exhaust temperatures and reduce energy consumption.

- Each heating zone is equipped with temperature sensors for real-time monitoring of billets, enabling gradient heating for precise temperature management.

- Operated via PLC and touchscreen, allowing manual, semi-automatic, and fully automatic control options for flexible operation.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos