Your One-Stop Solution for Complete Aluminum Profile Extrusion Line

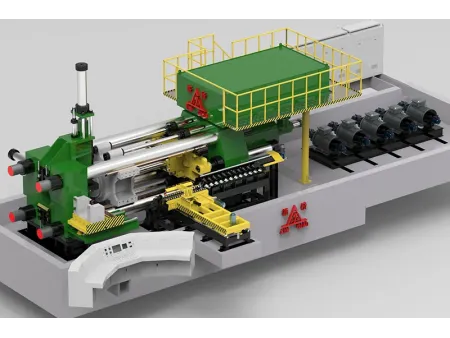

Long-Stroke Aluminum Extrusion Press (780-1100T)

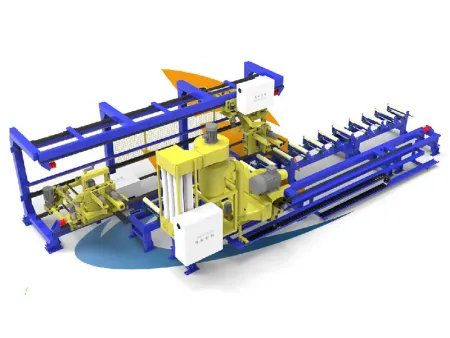

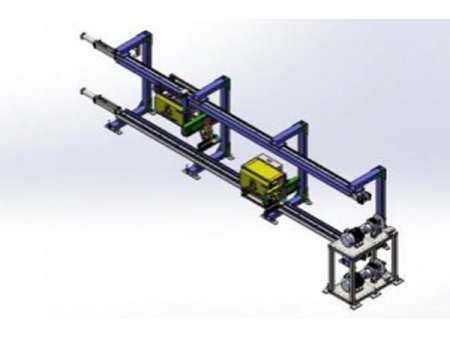

Fully Automatic Aluminum Profile Extrusion Line

Aluminum Extrusion Equipment

Electric-hydraulic hybrid extrusion press for manufacturing aluminum profiles

The electric-hydraulic hybrid extrusion press is designed for speed, precision, and stability. Driven by a servo motor, it ensures faster and more accurate feeding of aluminum billets into the extrusion press. The main structure features a pre-stressed composite frame, which effectively reduces the elastic deformation of guide posts and enhances aluminum extrusion precision and stability.

| Billet Size (Diameter×Length):Ø100×580mm | Piston Diameter:620mm |

| Working Pressure:23MPa | Dead Cycle Time:≦17s |

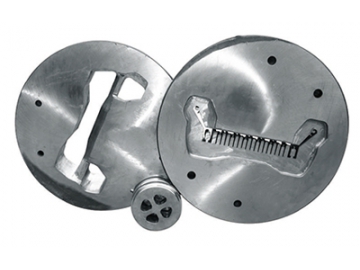

| Production Capacity (24 hours):6-7 tonnes | Die Size:Ø220×200mm |

| Outlet Size:Ø130×150mm | Max. Square Tube:78×78mm |

| Max. Flat Tube:125×28mm | Max. Round Tube:Ø110mm |

| Front Beam:380mm | Main Cylinder Seat:380mm |

| Weight:35t | Total Power:115kW |

| Hydraulic Pump:250L/min 210L/min | |

| Billet Size (Diameter×Length):Ø115×600mm | Piston Diameter:620mm |

| Working Pressure:26MPa | Dead Cycle Time:≦17s |

| Production Capacity (24 hours):6-7 tonnes | Die Size:Ø220×200mm |

| Outlet Size:Ø130×150mm | Max. Square Tube:78×78mm |

| Max. Flat Tube:125×28mm | Max. Round Tube:Ø110mm |

| Front Beam:380mm | Main Cylinder Seat:380mm |

| Weight:40t | Total Power:115kW |

| Hydraulic Pump:250L/min 210L/min | |

| Billet Size (Diameter×Length):Ø127×720mm | Piston Diameter:700mm |

| Working Pressure:26MPa | Dead Cycle Time:≦17s |

| Production Capacity (24 hours):14-15 tonnes | Die Size:Ø280×280mm |

| Outlet Size:Ø160×200mm | Max. Square Tube:100×100mm |

| Max. Flat Tube:175×30mm | Max. Round Tube:Ø140mm |

| Front Beam:530mm | Main Cylinder Seat:500mm |

| Weight:53t | Total Power:210kW |

| Hydraulic Pump:250L/min 280L/min | |

- Utilizes electric-hydraulic technology to maintain hydraulic oil temperature at room temperature

- Features non-welded oil pipes, achieving standardization, interchangeability, and eliminating welding debris and oxide layers, preventing oil circuit contamination

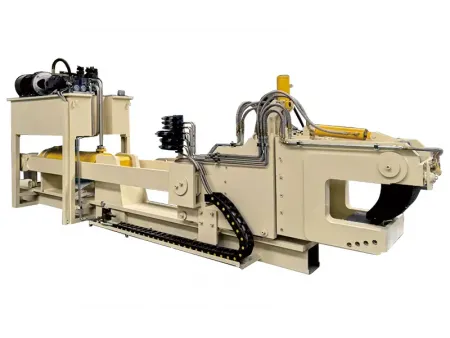

- Incorporates a fixed extrusion rod base with a movable extrusion head for a simple, stable, and low-fault design

- Shear blades and butt shear unit auxiliary actions are powered by a German Rexroth A15V plunger pump, using a variable pump for rapid and buffered movements, ensuring fast yet smooth operation.

- Equipped with a self-designed servo electronic scale for constant speed and precise positioning, entirely replacing the traditional stroke switch or proximity switch

The long-stroke aluminum extrusion press delivers superior precision, durability, and operational efficiency, making it a reliable choice for high-demand aluminum extrusion processes.

Hydraulic Oil Tank

The tank is divided into multiple compartments to reduce hydraulic oil vortex impact, eliminate bubbles, and prevent bubbles from entering the pump system, which could result in power loss.

Hydraulic Cylinder

Manufactured Hengli Pneumatic, the cylinder is made from alloy-enhanced materials for improved strength and precision. Its integrated one-piece design ensures no oil leakage.

Hydraulic Oil Tube

Uses Parker non-welded oil tubes from the United States, ensuring a small contact area during installation and no oil leakage

Tapered flange connections enhance sealing as pressure increases

Standardized length and angle for interchangeability and universality

Prevents the generation of welding debris and oxidation layers, protecting the oil circuit from contamination

Hydraulic Pump

Features the A4V industrial series from German manufacturer Rexroth, ensuring high-quality performance and reliability.

Direct Heating of Extrusion Press Container

Utilizes a controlled heating system with temperature gradients from low-to-high for uniform heating, avoiding cracking caused by direct heating.

Motor

Powered by Italian FEISHI motors for stability, strong performance, low noise, and energy efficiency.

Control System

Equipped with Siemens control systems, offering high stability and minimal maintenance. It avoids common failures associated with proximity switches in hydraulic systems.

Mobile Extrusion Rod Seat Universal Joint

Allows 360-degree rotation, preventing damage to gears and racks caused by positioning errors.

Butt Shear Unit

Uses Siemens systems for precise control of linear deceleration, ensuring the shear blade and butt shear unit quickly reach position with flexible contact, preventing damage.

Piston

Designed based on stress analysis, the piston features varying wall thicknesses and a bullet-shaped topology, effectively protecting it from impact and cracking.

Servo-Controlled Extrusion Scrap Detection

Siemens systems accurately control the servo encoder to detect the presence of extrusion scraps. In the absence of scraps, it prevents damage to the extrusion rod caused by improper extrusion.

Servo Manipulator

Siemens systems provide precise control for accurate positioning and easy adjustments, significantly reducing the manipulator's in-and-out time.

Noise Control

Hydraulic pump noise is controlled to ensure operating noise levels are maintained at approximately 86 decibels per device.

Servo Electronic Scale

Provides precise positioning, ensuring quick movement and stable hydraulic oil flow.