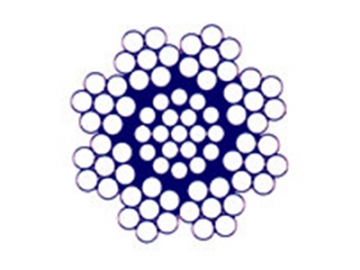

Wire Rope Sling, Mechanical Spliced

Strength of this wire rope sling has been improved from 70% of breaking load of hand-spliced slings and slings with clamps to 95%. Mechanical slicing make the wire rope closely coupled with the aluminum alloy sleeve while maintaining its original structure. As a result, splicing strength of the lifting sling is up to 100%, corrosion resistance is enhanced and wire rope's life time is prolonged by about 50%.

The aluminum alloy slice is come with test proven breaking strength and fatigue strength. It has no crack and no sliding as the wire rope is broken at nominal breaking load. It is completed made to GB standards and DIN standards.

Technical Parameter of the Wire Rope Sling| Model | Wire rope nominal diameter | Wire rope nominal tensile strength ( MPa ) | Splice Size | Wire rope classification | |

| 1670 | 1770 | A × B | |||

| Maximum load (KN) | mm | ||||

| 6~8 | 6.39 | 6.77 | 160 × 80 | 6 × 19 (b) | |

| 9~11 | 12.1 | 12.8 | 220 × 110 | ||

| 12~14 | 19.6 | 20.7 | 280 × 140 | ||

| 16~20 | 38.4 | 40.7 | 400 × 200 | 6 × 37 (b) | |

| 22~26 | 64.8 | 68.7 | 520 × 260 | ||

| 28~32 | 98.2 | 104 | 640 × 320 | ||

| 34~38 | 138 | 147 | 760 × 380 | ||

| 40~44 | 186 | 197 | 880 × 440 | ||

| 46~54 | 268 | 284 | 1080 × 540 | 6 × 61 (b) | |

| 58~64 | 377 | 399 | 1280 × 640 | ||

| 68~76 | 531 | 563 | 1520 × 760 | ||

| 78~82 | 700 | 741 | 1640 ×820 | 6 × 61 ( ab ) | |

| 84~88 | 805 | 853 | 1760 × 880 | ||

| 90~104 | 1125 | 1191 | 2080 × 1040 | ||

| 106~120 | 1497 | 1587 | 2400 × 1200 | ||

Note:

1. Parameters in the table are a result of sample tests, so they are only for reference purposes. They may vary slightly as the test methods or ambient environment change.

2. Junwei produce bespoke solutions to your specific requirements. Consult with us for details.