Gypsum Board Edge Sawing Machine

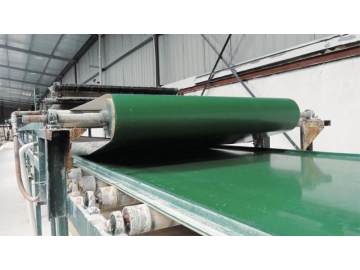

In the gypsum board production line, the edge sawing machine is mainly used to align the gypsum boards from the booker, and then performs horizontal cutting at a high speed to create gypsum boards with smooth and flat ends. After that, it transfers the gypsum board to the next stage for edge covering.

Features

1. One saw blade of the edge cutting machine is fixed. The other one is movable along the slide way so as to allow for cutting width adjustment.

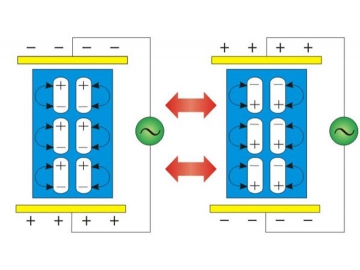

2. Dual band-type brakes are available to ensure reliable stopping of the movable blade.

3. Supporting control via a PC, the cutting equipment can realize automatic cutting width adjustment.

4. Both sides of the sawing machine are designed with a large power dust collector which effectively prevents dust pollution.

5. Easy for maintenance

Main Technical Parameters of the Edge Saw

Height of inlet: 1080mm

Max. gypsum board length: 1800~3600mm

Saw blade drive motor power: 7.5kW×2, 1.5kW×2

Power of infeed motor: 5.5Kw

Power of roller conveyor driven motor: 0.55×2kw

Power of width-adjustment motor: 1.1kW

Power supply requirement: 400V/50Hz

- Sawing machine

- Saw blade

- Slide way for the movable blade

- Dust collecting piping