CNC Rebar Double Bender

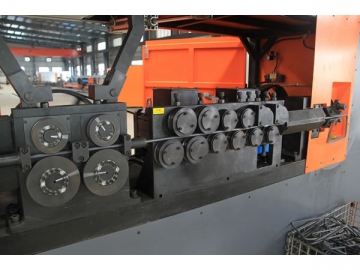

SKZ CNC rebar double bender (Mode: KZ2L32)

Brief IntroductionThe CNC rebar double bender is widely used for rebar bending in high rise buildings, highways, railways, large scale bridges and other reinforced concrete structures. Our rebar double bender bends III class rebar of φ32mm (HRB400) in 2 directions during 1 working cycle. In order to satisfy ever changing market demands, we have independently researched and developed this particular type of CNC rebar double bender, which is known for its high degree of processing precision and working efficiency. It meets the requirements and standards of numerous construction projects. Each rebar bending machine generally does the work of 8 to 10 human operators, thus reducing the labor costs and improving the efficiency to bring increased benefits.

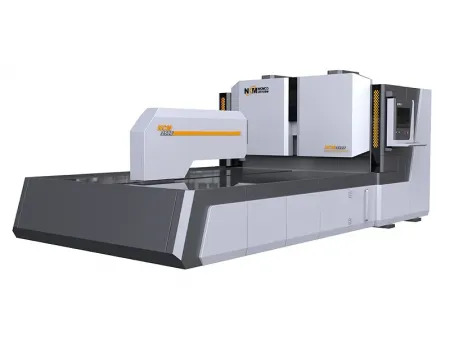

Important Advantages of Our Bar Bender1. The high performance PLC (Programmable Logic Controller) and touchscreen ensure easy and simple operation.

2. A flexible central rebar lock design ensures the bending precision.

4. The bending shaft is controlled using a servo motor, achieving a high bending precision.

5. A moveable bending unit allows for flexible sizing of the bending length.

6. An all in one structural design and high strength rail contributes to the durability.

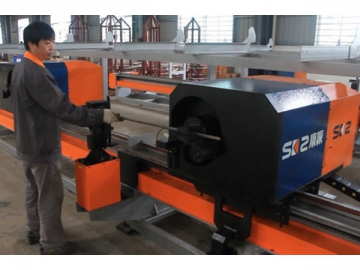

8. The retractable shaft ensures the rebar and be bent in 2 different directions.

9. The high strength material rack features an excellent loading capacity.

10. The CNC steel bending instrument is able to simultaneously bend several rebars into different angles.

13. The metal bender also has an excellent adaptability. It can process III class rebar of Φ10-32 (HRB400).

Technical Parameters

| Model | KZ2L32 | ||||||||||

| Max bending angle ( °) | φ6-φ28 | 180 0 | |||||||||

| -120 0 | |||||||||||

| φ32 | 90 0 | ||||||||||

| -90 0 | |||||||||||

| Max Bending Size (mm) | 10500 | ||||||||||

| Min Bending Size (mm) | 90 | ||||||||||

| Min bending length (mm) | (φ10),(630mm) | ||||||||||

| (φ25),(650mm) | |||||||||||

| Length error(mm) | ±2 | ||||||||||

| Bending error ( ° ) | ±1 | ||||||||||

| Speed control | CNC Servo control | ||||||||||

| Installed power(KW) | 14 | ||||||||||

| Installed voltage | 380V 50Hz | ||||||||||

| Moving speed(m/s) | 0.2-0.9 | ||||||||||

| Bending speed ( ° /s) | 65 | ||||||||||

| Working temperature (℃) | 0-40 | ||||||||||

| Cylinder pressure(Mpa) | 0.6 | ||||||||||

| Manufacture range | Strand Diameter φ(mm) | 10 | 12 | 14 | 16 | 20 | 22 | 25 | 28 | 32 | |

| Nos .to be sheared(pcs) | 6 | 5 | 4 | 3 | 3 | 2 | 2 | 1 | 1 | ||

| Weight(kg) | 4500 | ||||||||||