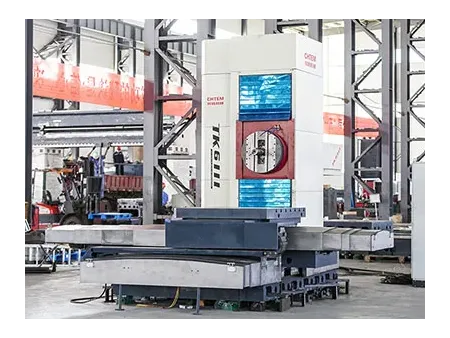

CNC Table Type Boring and Milling Machine

Primarily designed for high-performance boring and milling, our CNC table type boring and milling machines also excel at drilling, reaming, and plane milling operations. They are exceptionally suited for processing box-type parts, frame components, and molds where precise hole spacing is critical. A key advantage is the ability to complete multiple processes—milling, boring, drilling, reaming, and tapping—in a single workpiece clamping, significantly enhancing productivity. These machines offer sophisticated six-axis control with four-axis simultaneous linkage, enabling complex operations like circular interpolation and the machining of 3D curved surfaces.

This machine is widely used for the machining of box-type components, frame structures, and mold parts.

| Model | ||

| Spindle Speed (rpm) | 2-2000 | 2-2000 |

| Spindle Diameter (mm) | ∅110 | ∅130 |

| Spindle Travel (W-Axis) (mm) | 600 | 800 |

| Max. Load Capacity of Worktable (T) | 5 | 8 |

| Model | ||||

| Worktable Size (L×W) | 1250×1400mm | 1400×1600mm | ||

| Spindle Diameter | ∅110mm | ∅130mm | ||

| Transverse Travel of Worktable (X-Axis) | 1800-2000mm | 1800-2000mm | ||

| Vertical Travel of Headstock (Y-Axis) | 1200-1600mm | 1600-2000mm | ||

| Longitudinal Travel of Worktable (Z-Axis) | 1200-1600mm | 1200-2000mm | ||

| Spindle Travel (W-Axis) | 600mm | 800mm | ||

| Worktable Rotation (B-Axis) | CNC control | CNC control | ||

| T Slot (Width×Pitch) | 22×125mm | 22×125mm | ||

| Max. Load Capacity of Worktable | 5T | 8T | ||

| CNC Controller | SIEMENS 828D or FANUC OI MD | |||

| Quantity of Axes | X/Y/Z/W(U) 4 axes (5 axes) | X/Y/Z/W(U) 4 axes (5 axes) | ||

| Spindle Taper | BT50(P50T-1) | |||

| Spindle Speed | 2-2000rpm | 2-2000rpm | ||

| Main Motor Power Torque | 18kW (1300Nm) | 30kW(2200Nm) | ||

| Max. Boring/Drilling Diameter | ∅240mm/250mm | ∅300mm/80mm | ||

| Max. Feeding Force on Spindle | 13000Nm | 23000Nm | ||

| Rapid Traverse of X/Y/Z Axes | 3000mm/min | 3000mm/min | ||

| Feeding Speed of X/Y/Z Axes | 5-1000mm/min | 5-2000mm/min | ||

| Feeding Speed of W-Axis | 0.5-1000mm/min | 5-2000mm/min | ||

| Rapid Traverse of W-Axis | 2000mm/min | 2000mm/min | ||

| Radial Travel of Facing Head Tool Holder | 160mm | 200mm | ||

| Facing Head Speed | 4-125rpm | 2-125rpm | ||

| Max. Machining Diameter of Facing Head Tool Holder | ∅630mm (optional) | ∅800mm (optional) | ||

| Max. Allowable Torque on Facing Head | 1300Nm (optional) | 2600Nm (optional) | ||

| Feeding Speed of Facing Head | 0.2-500mm/min (optional) | 0.2-500mm/min (optional) | ||

| Rapid Traverse of Facing Head Tool Holder | 1000mm/min (optional) | 1000mm/min (optional) | ||

| Positioning Accuracy of X/Y/Z Axes (Full Travel) (GB/T17421.2-2000) | 0.026/0.03/0.03mm | 0.03/0.03/0.03mm | 0.04/0.03/0.03mm | 0.03/0.03/0.03mm |

| Positioning Accuracy of W-Axis (Full Travel) (GB/T17421.2-2000) | -- | 0.03mm | ||

| Positioning Accuracy of B-Axis Rotation | 0.08' | |||

| Repeatability Accuracy of X/Y/Z/W Axes (Full Travel) (GB/T17421.2-2000) | 0.015/0.015/0.015mm | 0.015/0.015/0.015/0.015mm | ||

| Repeatability Accuracy of B-Axis Rotation | 6' | |||

| Machine Dimensions (L×W×H) | 6.3×3.9×3.7m | 6.5×4.2×3.9m | ||

| Machine Weight | 25T | 32T | ||

The CNC table type boring and milling machine primarily consists of the (machine) bed, column, headstock, saddle, transverse saddle, worktable, lubrication and cooling systems, and the electrical system.