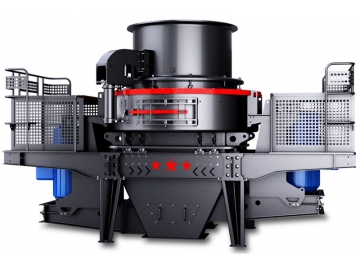

Vertical Compound Crusher

Detailed Description of Vertical Compound Crusher

Henan Hongji optimizes the key structural parameters to develop vertical compound crushers for grinding raw materials for cement and cement clinker in cement factories. This is done based on a combination of pre-breakage technology from China and foreign countries.

Our vertical compound crusher, which is suitable for primary and secondary crushing, has the characteristics of reliable performance, low power consumption, and easy maintenance, etc.

Applications of Vertical Compound Crusher

Our vertical compound crusher can be used to crush various materials, such as aluminum ore, coal gangue, phosphorus ore, stone, granite, trap rock, limestone, manganese ore, gypsum, lump coal, oxide, fused calcium carbide, emery, coke, iron ore, fused aluminum and so on.

Besides, our vertical compound crushing machine can also be used in other fields such as for building materials, metallurgy, in the mining industry and chemical industry, etc.

As a vertical compound crusher manufacturer and supplier in China, Henan Hongji Mine Machinery Co., Ltd. provides many crushing machines, such as cone crusher, roll crusher, impact crusher, ring hammer crusher, and so on. Our crushers have passed ISO9001:2000 quality system certification and SGS certification. They are recommended by leading consultants in the crushing field and are used by hundreds of customers in Vietnam, Bengal, Myanmar, Laos, Peru, Philippines, Iran, India and other countries.

Specifications of Vertical Compound Crusher| Model | |||||

| Rotor diameter(mm) | 650 | 800 | 1000 | 1250 | |

| Cylinder height(mm) | 800 | 850 | 850 | 1000 | |

| Main shaft Rotation speed(Rotation/min) | 930 | 769 | 530 | 495 | |

| Feeding size(mm) | 50 | 70 | 100 | 100 | |

| Discharging size(mm) | 0-5 | 0-5 | 0-5 | 0-5 | |

| Processing capacity(t/h) | 5-15 | 10-30 | 20-60 | 30-80 | |

| Motor | Model | Y Series-4 | Y Series-4 | Y Series-8 | Y Series-8 |

| Power(kw) | 30 | 55 | 75 | 110 | |

| Rotation speed | 1440 | 1440 | 750 | 750 | |

| Dimensions(L*W*H) | 2200*860*1980 | 2700*1160*2000 | 2800*1400*2730 | 3100*1900*2300 | |