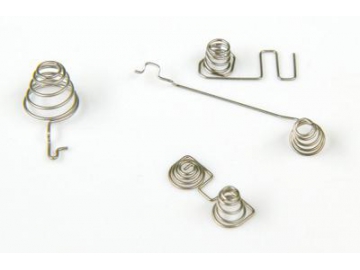

Compression Springs

Juneng provides custom compression springs for clients. With the unique property of bearing axial pressure, compression spring has found wide applications like: springs for locomotive, vehicle, and tank locomotive; leaf spring, buffer springs, tension springs for automobile, springs for pump plunger, injector spring, valve spring for agricultural diesel engine, and valve spring for heavy-duty vehicles, etc. The 2 ends of compression springs can be open-ended, closed-ended, pigtail or reduced on center. Most of them are made from steels with circular cross section, with a small part coiled from rectangular steels or steel wire ropes. Compression springs with either variable or equal pitch are available.

Technical Parameters| Material | stainless steel, carbon steel, alloy steel, 60Si2Mn, 65Mn, spring steel |

| Wire diameter | 0.2mm-100mm |

| Customization | springs are customized basing on clients' drawings, sample, and dimension |

| Surface treatment | painting, coating ,galvanizing, flanging, or others upon customers' request |

| Color | as customers' request |

| Packaging | wooden box |

Compression springs feature various shapes, like cylindrical, conical, irregular shapes, narrow at ends and wide in middle, and wide at ends but narrow in middle. Almost any spring shape needs will be met here in Juneng. There will be certain space between spring coils so that the spring will compress and store the elastic energy will loaded.

Applications

Among all kinds of springs, compression spring is the most commonly used one. Its applications include electronics, motor, computer, information, steam locomotive, bicycle, hardware tools, gifts, toys, and even defense industries.

Hardening Treatment for Compression Springs

1. Shot Peening

For processing a batch of compression springs, we can firstly transport the springs one by one to the shot blasting machine, which is equipped with a set of parallel rollers to drive the springs to move as rotating. The purpose of this style of movement is to let the high-speed particles pass each coil of the springs and hit on the spring's inner surface, where the stress concentrates the most. Shot peening is the best strengthening method for suspension spring. After a blasting treatment, the life of high-stress springs can be extended by at least 4 times.

2. Heat Treatment

Different heat treatment process leads to different spring hardness. For quenching temperature of 785-815℃, and tempering temperature of 300℃, 400℃, 500℃, 600℃, the hardness is respectively HB512, HB430, HB369, and 75; for quenching temperature of 780-800℃, and tempering temperature of 400-420℃, the spring hardness is HRC42-48.

Customizing

1. After receiving clients' drawings, samples or spring dimensions, we will discuss with clients to determine some details, and then the production will start. Technical advisory service is offered for free.

2. Product report and testing result will be sent to customers together with the springs.

Why Choose Us

1. We offer custom springs exactly according to clients' requirements

2. Juneng provides you comprehensive and considerate

3. DN high-speed quenching oil developed by Nanjing University of Aeronautics and Astronautics is used as the quenching medium. It has greatly reduced the deformation and cracking during quenching, as well as improved the hardness of springs.

4. With 3 large CNC salt bath tempering furnace, the internal stress of the springs is eliminated uniformly

5. 6 sets of end grinding machines and M4013 double-end grinding machine are adopted to prevent the overheating phenomenon occurred during grinding

6. Sand blasting is finished by a large suspended rotary shot blasting machine, ensuring a large surface hardness and long service life.

7. We use an advanced CJW-6000 magnetic particle flaw detection machine to check the internal flaws of the heat treated springs,