Digital Cutter for Composite Material

Request a Quote

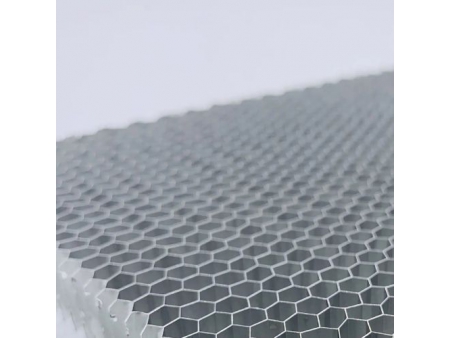

- Aluminum Honeycomb Core

- Carbon Prepreg

- Dry Carbon Fiber Fabric

- Fiberboard

- Nomex Honeycomb Core

- 5mm Thick Mouse Pad Cutting

- Carbon Prepreg Cutting

- Glassfiber Cutting

- TPU Sheet Cutting

-

Modular combination of cutting knives:

high speed rotary knife, high speed oscillating knife for cutting various types of composite materials including glass fiber, carbon fiber prepreg composites, carbon fiber fabric, etc.; -

Anti-collision device infrared light curtain:

protecting operator from being injured; -

Advanced software:

independently developed by Sinajet, providing users with intelligent operation experience while fulfilling their various cutting demands; -

Exclusive material hold-down technology:

low noise level and reduced energy consumption;

Options

There are six models available to meet different needs. Those models vary from the cutting area (L*W). Customized machine model can be offered upon request.

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Working table: fixed table and conveyor table are optional

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, oscillating knife, V-cutting tool, drilling tool

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 2.2-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

Sinajet provides solutions tailored to customers’ needs of various composite materials cutting. Our modular combination of cutting tools can meet your individual cutting demands for a variety of materials, such as carbon fiber, glass fiber, ETFE, PVE, HYPALON, etc., providing a high speed, precise and stable cutting operation.

Features

-

Digital Cutting of Glass Fiber for Wind Turbine Blades

Cutting of four layers of glass fiber 1200g/m2;

Synchronous feeding of four layers of glass fiber, and automatic collection; -

Digital Cutting of Carbon Fiber Prepreg Composites and Carbon Fiber Fabric

Cutting solution for carbon fiber in aviation and railway industries; -

Digital Cutting of Conveyor Belt Material

Using oscillating knife for cutting of high-strength conveyor belt;

-

Digital Cutting of PET film

Using oscillating knife and rotary knife for cutting PET film and membrane foil; -

Plotting Pen Module

Marking of cut pieces; -

Inkjet Module

Marking of cut pieces;

-

Automatic Feeding Automatic Cutting Automatic Collection

Accomplishing automatic process from feeding, cutting to finished product collection; -

Automatic Feeding Unit

Achieving synchronous feeding of roll materials when cutting machine is working;