Ductile Iron Pipe Mould

TongYu is the largest production base of ductile iron pipe mould in Asia. Our pipe moulds are available mainly in diameter from DN50 to DN2600mm. Ductile iron pipe mould is a compulsory tool in producing ductile iron pipe. It is rather expensive and its price takes a large proportion in the production cost of casting pipes. So it is of great significance to improve the quality of pipe molds and extend their life.

It has been proven that, the performance and service life of our pipe moulds is competent with that of the moulds produced in America and Germany. TungYu ductile iron pipe moulds have been applied in various large casting pipe manufactures in China, and exported to many regions like Japan, and Southeast Asia.

Specifications of Pipe Moulds| Material | 21CrMo10 |

| Types | water-cooled metal pipe mould, hot molding pipe mould |

| Specification | DN50-2600mm |

Manufacturing Process

Raw Material Smelting – LF Refining – Vacuum Degassing – Iron Ingot Casting – Forging – Heat Treatment – Roughing – Quenching and High-Temperature Tempering – Semi-Finishing – Stress Relieving – Finishing – Packaging

All of the steps from smelting, forging, heat treatment, flaw detection, to mechanical processing are controlled strictly and accurately.

Quality Control

1. During the smelting process, strict control is required both for the prescribed elements (21CrMo10), and for some harmful elements and gas, like P, S, Pb, Sn, As, Sb, Bi, and H, O, N.

2. To guarantee that the pipe moulds have reached our flaw detection standards, and that the forged blanks own refined grains, we have employed strict forging technique upon the ductile iron pipe moulds.

3. After roughing process (drilling inner holes), a quenching and tempering treatment is given by vertical pit furnace upon the pipe moulds for further refined grains and higher comprehensive mechanical properties.

4. CNC equipment is adopted for finishing for high processing precision.

5. All of the properties of our pipe moulds are superior than the GB/T 25715 centrifugal ductile iron pipe mould standards.

DN500mm-1168mm ultra-supercritical pressure boiler pipe for power station

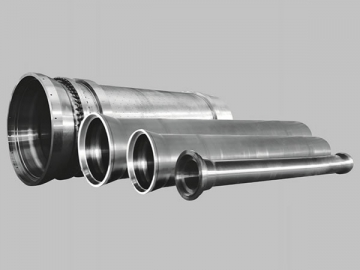

Small pipe moulds

DN2600 pipe mould

DN2600 pipe moulds

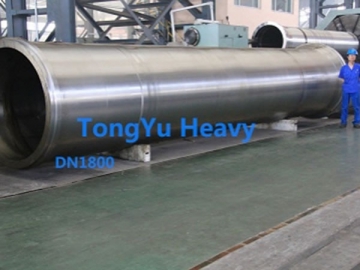

DN1800 pipe moulds

DN1800 pipe moulds