GC 4 4 - 850

Request a Quote

CI Flexo Printing Press

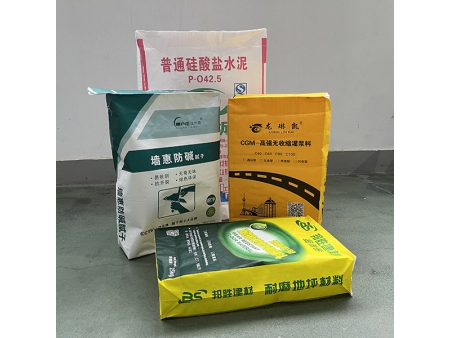

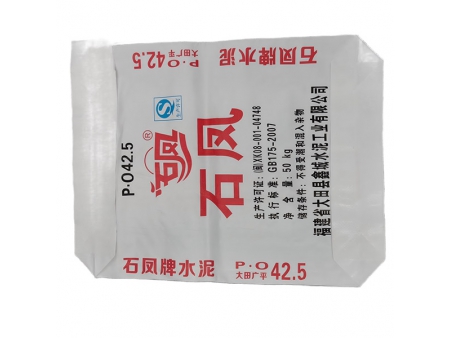

Applications:- Woven bags: High-speed, double-sided printing on PP/PE materials.

- Label films: Precision registration for tension-sensitive substrates.

- Reliable packaging: Clean printing environment for pharmaceutical and food-grade applications.

Video Show

Print Samples

Why Choose CI Flexo Printing Presses?

- Central design: Substrates stay close to CI drum, cutting tension fluctuations by 50%.

- European-standard engineering: Over 80% of key components are imported, extending machine lifespan up to 3×.

- One-touch operation: Pre-registration with fully automated running and hydraulic auto-reset.

- Energy-efficient system: Smart PID-controlled drying reduces power consumption by 15%.

Specifications

| Web Width | 800mm |

| Max. Printing Width | 760mm |

| Substrate | PP woven fabric |

| Plate Thickness | 1.14 / 1.70 / 2.28 / 2.84 / 3.94 mm (customizable) |

| Printing Repeat Length | Standard 400 mm (customizable 380–800 mm) |

| Registration Accuracy | |

| Lateral Registration | ±0.15mm |

| Longitudinal Registration | ±0.15mm |

| Press Type | Central Impression (CI) drum |

| Gear Module | 1.5mm |

| Drying Technology | Electric heating |

| Maximum Temperature | Up to 80 °C (ambient 20 °C) |

| Unwind/Rewind Reel | 3-inch |

| Max. Unwind/Rewind Diameter | 1500mm |

Features

- Registration AccuracyFully servo driven and equipped with advanced online monitoring, the flexo printing press ensures registration accuracy within ±0.15 mm in both cross and machine directions. Even at high speeds or sudden shifts, precision remains stable, minimizing waste and delivering flawless alignment for premium packaging and label applications.

- Web Substrate ExpertiseEngineered for stable handling of 550–850 mm materials, especially PP woven fabric and PE films with low tension. Equipped with sensitive floating rollers and tension control, it overcomes common issues of stretching and misalignment, ensuring continuous high-speed, non-stop operation.

- Durable Imported ComponentsCore systems use top-tier international brands: chamber doctor blade technology from Denmark reduces solvent evaporation; German web guiding ensures zero deviation; Japanese servo motors deliver precise positioning. With over 80% of critical components imported, the press provides exceptional reliability, long-term stability, and higher ROI through reduced downtime.

- Double-Sided PrintingFeaturing an innovative 4 4 CI (Central Impression) press design, the machine prints four colors on the front and four on the back simultaneously. This eliminates material flipping and secondary web runs, completing both sides in a single pass. The result is significant time and labor savings, perfectly suited for woven bags, shopping bags, and industrial packaging in high-volume production.

- Intelligent Temperature ControlThe central impression drum features a dual-layer hollow design with PID smart temperature regulation, maintaining surface variation within ±1 °C. This prevents substrate distortion and uneven ink curing, guaranteeing consistent color stability across long production runs.

1 Unwinding Unit

- Size: 6" / 8" (customizable)

- Max. material diameter: 1500 mm

- Material weight: 500–1800 kg

- Automatic roll change without downtime

2 Web Guiding System

- Automatic web guiding control

- Four-roller guiding, ±65 mm lateral adjustment

- Floating guides positioned before and after printing for precise registration

3 Rewinding Unit

- Size: 6" / 8" (customizable)

- Max. material diameter: 1500 mm

- Material weight: 500–1800 kg

- Automatic roll change without downtime

- Equipped with servo-driven blade

4 Corona Surface Treatment

- Enhances surface tension for superior ink adhesion

1 Plate Cylinder

- Print length: 400–1000 mm.

2 Anilox Roller

- Delivers uniform ink transfer

- Range: 100–1000 LPI

- Customizable per customer requirements

3 Chamber Doctor Blade

- Aluminum alloy body with Danish technology

- Leak-free operation at high speeds

- Compact design reduces solvent evaporation

- Teflon-coated surface for durability

4 Ink Pump

- Automatic ink circulation system

- Dual-diaphragm pump design

- Prevents ink drying during operation

5 Register

- Motorized longitudinal and transversal control of print registration

- Integrated with PLC and video inspection

6 Inspection System

- Dual-camera, single-lens design

- Size: 540 × 940 mm

- Resolution: 3840 × 2160

- Inspection switch speed: 1.0 m/min