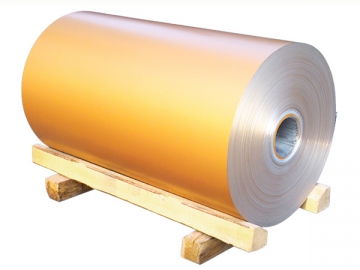

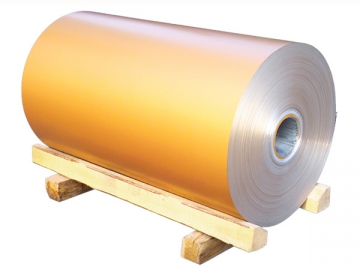

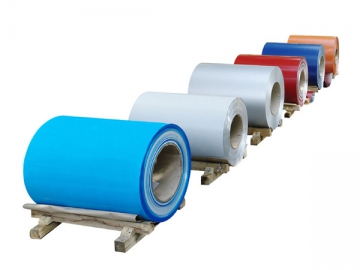

PVDF Coated Aluminum Coil

PVDF Coated Aluminum Coil

PVDF coated aluminum coils are the highest priority of choice to high classaluminum composite panels, and its composite products are widely used inairport, exhibition center, administration center, star hotel and other symbolbuilding.

Performance of the Coating

| Aluminum Thickness | Coating Thickness | MEK | T | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

| 0.3-1.5 ㎜ | ≥25μm | ≥100 Times | ≤2T | 50 ㎏ • ㎝ | 0 Grade | ≥HB | no change within 2 hours |

| 0.15-0.28 ㎜ | ≥25μm | ≥100 Times | ≤2T | 20 ㎏ • ㎝ | 0 Grade | ≥HB | no change within 2 hours |

The Performance of PVDF Coated Coil

| Item | Test Item | Standard | National Standard | Test Result |

| 1 | Color difference | ECCA T3 | Δ E ≤ 2.0 | Δ E ≤ 1.0 |

| 2 | Gloss | ECCA T2 | Difference ≤ 10 | Difference ≤ 5 |

| 3 | Coating thickness | ECCA T1 | 23µm Two coatings Min 23µm | ≥ 25µm |

| 3 Three layers Min 30µm | ≥ 34µm | |||

| 4 | Pencil hardness | ECCA T4 | ≥ HB | HB |

| 5 | T-bend | ASTM D4145 | ≤ 2T | ≤ 2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥ 50kgNaN | ≥ 50kgNaN |

| 8 | Boiling water resistance | GB/T17748 | 2hrs No change | 4hrs No change |

| 9 | Solvent resistance | ASTM D2248 | 200 times paint remaining | 500 times paint remaining |

| 10 | Acidity resistance | ASTM D1308 | 5%HCL 24h No change | No change |

| 11 | Alkali resistance | ASTM D1308 | 5%NaOH 24h △ E ≤ 2.0 | No change |

| 12 | Nitric acid resistance | AAMA620 | △ E ≤ 5.0 | △ E ≤ 5.0 |

| 13 | Oil resistance | ASTM D1308 | 20 # oil 24hrs No change | No change |

| 14 | Salt fog resistance | ASTM B117 | 4000hrs ≤ Grade 11 | No change |

| 15 | Abrasion Resistance | ASTM D968 | ≥ 5L/µm | ≥ 5L/µm |

| 16 | Dirt resistance | GB/T9780 | ≤ 5% | < 5% |

| 17 | Color retaining | GB/T16259 | 4000hrs ,△ E ≤ 4.0 | △ E ≤ 3.0 |

| 18 | Gloss losing level |

| 4000hrs ≤ Grade 2 | ≤ Grade 2 |

| 19 | Chalking |

| 4000hrs No change | No change |