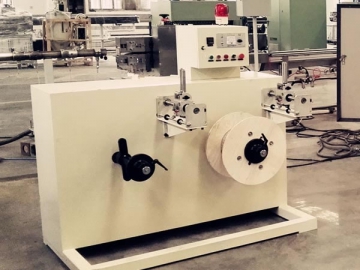

3D printer filament extrusion machine

3D Printer Extrusion Machine / Printer Filament Extrusion Machine / Filament Extrusion Machine

3D printing is a rapid prototype technology, and is a print technology based on a digital model file. Materials are constructed, or "printed" using powder metal or plastic adhesive materials in a step by step process.

The shape of the 3D printer plastic filament is a solid round wire, with a primary raw material of PLA, PVA, HIPS, ABS or PC, ranging in diameter from 1.75 to 3.0mm in diameter. Kingswel Baodie Company provided the first set of 3D printer filament extrusion machines to a client in 2009, and after several years of continuous improvement of equipment configuration and extrusion technology, we have developed a set of specialized line of 3D printing consumables extrusion line. When matched with different screw and molding technologies, it can meet PLA, PVA, HIPS, ABS, and PC consumable material production requirements.

Features of the 3D Printer extrusion machine line:

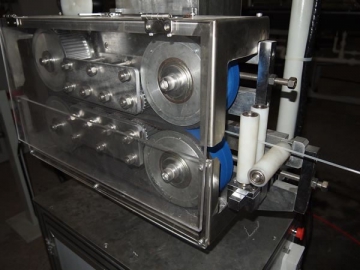

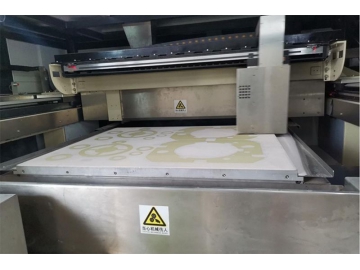

1. The entire extrusion line is equipped with a full servo drive, ensuring a high running process for each part on the extrusion production line, including melt extruding, melt metering, pulling and other processes.

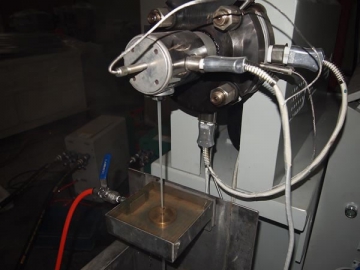

2. The 3D printer filament extrusion line is also equipped with a metering pump system, redoubled to ensure precision of the melt flow, and an increase in the die head pressure avoids hollow wire interiors.

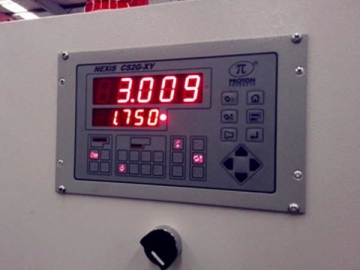

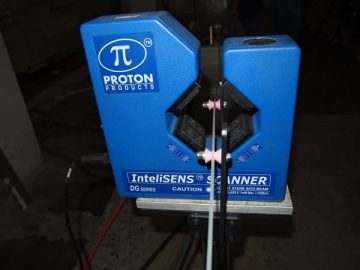

3. Equipped with an online diameter laser gauge and automatic diameter feedback control functions, control of the dimension tolerance is held to a minimum value, thus raising the level of automation for the entire line.

Basic parameters:

- Production speed: DN1.75mm 80-100m/min, DN3.0mm 35-45m/min.

- Control accuracy: Φ3.0 mm to 2.9 mm, 1.70 to 1.80 mm. ( /-0.05mm, CPK≥1.6)

Extrusion molding:

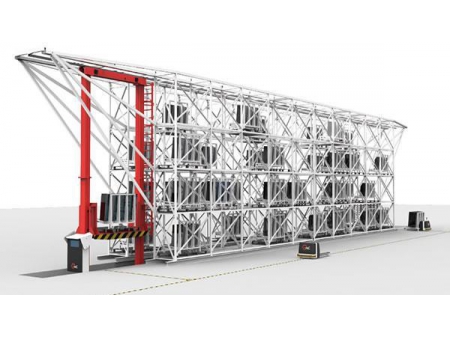

First step large roller coiling, then from large roller to standard roll coiling: