Mechanical Tee Grooved Outlet

Request a Quote

Grooved ductile iron pipe fittings

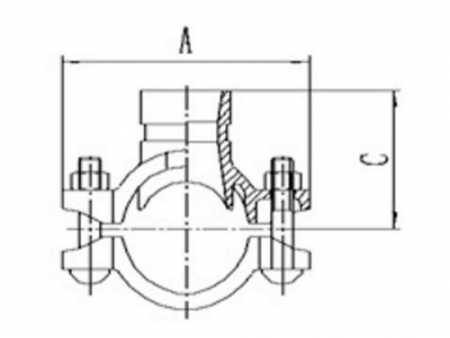

Mechanical tee grooved outlet consist of upper and lower plates, a gasket, and bolts/nuts, providing a simple and fast method for branch connection. The self-sealing structure of the gasket ensures permanent sealing. During field operations, mechanical tees can be precisely installed on the pipeline to ensure the accuracy of the branch outlet connection.

Features

- Mechanical tee grooved outlet provides an additional grooved outlet in existing piping.

- For new construction, using of a mechanical tee eliminates the need for reducing tees.

- The mechanical tee may be easily converted into a cross when necessary.

Recommended Applications

Mechanical tee grooved outlet are suitable for grooved piping systems, such as fire protection systems and sprinkler piping systems.

Key Specifications

- Available sizes: 2×1 inch~10×4 inch |DN50×25~DN250×65

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Material: ductile iron

Specifications

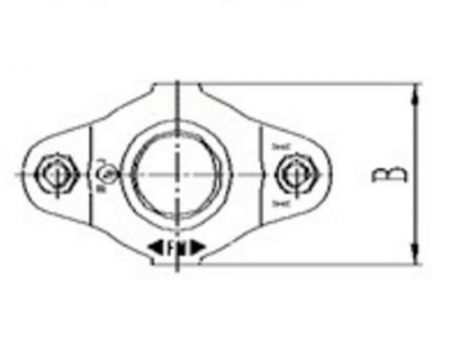

| Nominal Size | Pipe OD. | Hole Dia | Dimensions | Bolt Size | |||

| mm/in | mm/in | A mm | B mm | C mm | D mm | ||

| 50x25 / 2x1 | 60x33.7 / 2.375 x 1.33 | 38 / 1.496 | 118 / 4.65 | 74 / 2.91 | 68 / 2.68 | 40 / 1.57 | M10x55-2 |

| 50x32 / 2x1 1/4 | 60.3x42.4 2.375 x 1.660 | 45 / 1.77 | 118 / 4.65 | 74 / 2.91 | 68 / 2.68 | 40 / 1.57 | M10x55-2 |

| 50x40 / 2x1 1/2 | 60.3x48.3 2.375 x 1.900 | 45 / 1.77 | 118 / 4.65 | 74 / 2.91 | 68 / 5 2.7 | 40 / 1.57 | M10x55-2 |

| 65x25 / 2 1/2x1 | 73x33.7 / 2.874 x 1.33 | 38 / 1.496 | 132 / 5.197 | 74 / 2.91 | 75 / 2.953 | 47 / 1.850 | M12×70-2 |

| 65x32 / 2 1/2x1 1/4 | 73x42.4 / 2.874 x1.660 | 51 / 2.01 | 132 / 5.197 | 84 / 3.31 | 75 / 2.953 | 47 / 1.850 | M12×70-2 |

| 65x40 / 2 1/2x1 1/2 | 73x48.3 / 2.874 x 1.900 | 51 / 2.01 | 132 / 5.197 | 84 / 3.31 | 75 / 2.953 | 47 / 1.850 | M12×70-2 |

| 65x32 / 2 1/2x1 1/4 | 76.1 x42.4 3.000x1.660 | 51 / 2.01 | 135 / 5.31 | 84 / 3.31 | 78 / 3.07 | 48 / 1.89 | M 12x70-2 |

| 65x40 / 2 1/2x1 1/2 | 76.1x48.3 3.000x1 900 | 51 / 2.01 | 135 / 5.31 | 84 / 3.31 | 78 / 3.07 | 48 / 1.89 | M12x70-2 |

| 65x50 / 2 1/2x2 | 76x60 / 3.000x2.375 | 51 / 2.01 | 135 / 5.31 | 84 / 3.31 | 78 / 3.07 | 48 / 1.89 | M12x70-2 |

| 80x25 / 3x1 | 89x33 / 3.500x1.33 | 38 / 1.496 | 146 / 5.75 | 74 / 2.91 | 83 / 3.268 | 55 / 2.17 | M12x70-2 |

| 80x32 / 3x1 1/4 | 88.9x42.4 3.500x1.660 | 51 / 2.01 | 146 / 5.75 | 86 / 3.39 | 85 / 3.35 | 55 / 2.17 | M12x70-2 |

| 80x40 / 3x1 1/2 | 88.9x48.3 3.500x1 900 | 51 / 2.01 | 146 / 5.75 | 86 / 3.39 | 85 / 3.35 | 55 / 2.17 | M12x70-2 |

| 80x50 / 3x2 | 88.9 x 60.3 3.500 x 2.375 | 64 / 2.52 | 146 / 5.75 | 96 / 3.78 | 85 / 3.35 | 55 / 2.17 | M12x70-2 |

| 80x50 / 3x2 1/2 | 88.9x73 / 3.500x3.000 | 64 / 2.52 | 146 / 5.75 | 96 / 3.78 | 85 / 3.35 | 55 / 2.17 | M12x70-2 |

| 100x25 / 4x 1 | 114x33 / 4.500 x 1.33 | 38 / 1.496 | 178 / 7.01 | 74 / 2.91 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x32 / 4x 1 1/4 | 114.3x42.4 4.500 x 1.660 | 51 / 2.01 | 178 / 7.01 | 86 / 3.39 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x40 / 4x1 1/2 | 114.3x48.3 4.500 x 1.900 | 51 / 2.01 | 178 / 7.01 | 86 / 3.39 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x50 / 4x2 | 114.3x60.3 4.500x2.375 | 64 / 2.52 | 178 / 7.01 | 100 / 3.94 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x65 / 4x2 1/2 | 114.3x73.0 4.500x2.875 | 70 / 2.76 | 178 / 7.01 | 106 / 4.17 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x65 / 4x2 1/2 | 114.3x76.1 4.500 x 3.000 | 70 / 2.76 | 178 / 7.01 | 106 / 4.17 | 98 / 3.86 | 69 / 2.72 | M12x75-2 |

| 100x80 / 4x3 | 114.3x88.9 / 4.500 x 3.500 | 89 / 3.5 | 178 / 7.01 | 124 / 4.882 | 99 / 3.898 | 69 / 2.72 | M12x75-2 |

| 125x40 / 5x1 1/2 | 139.7x48.3 5.500x1.900 | 51 / 2.01 | 213 / 8.39 | 86 / 3.39 | 110 / 4.33 | 81 / 3.19 | M16x85-2 |

| 125x50 / 5x2 | 139.7x60.3 5.500 x 2375 | 64 / 2.52 | 213 / 8.39 | 102 / 4.02 | 110 / 4.33 | 81 / 3.19 | M16x85-2 |

| 125x65 / 5x2 1/2 | 139.7x76.1 5.500x3.000 | 70 / 2.76 | 213 / 8.39 | 108 / 4.25 | 110 / 4.33 | 81 / 3.19 | M16x85-2 |

| 125x80 / 5x3 | 139.7x88.9 / 5.500x3.500 | 89 / 3.5 | 213 / 8.39 | 124 / 4.882 | 110 / 4.33 | 81 / 3.19 | M16x85-2 |

| 150x50 / 6x2 | 165.1x60.3 / 6.500x2.375 | 64 / 2.52 | 238 / 9.37 | 100 / 3.94 | 125 / 4.92 | 95 / 3.74 | M16x 105-2 |

| 150x65 / 6x2 1/2 | 165 1x73.0 / 6.500x2.875 | 70 / 2.76 | 238 / 9.37 | 108 / 4.25 | 129 / 5.08 | 95 / 3.74 | M16x 105-2 |

| 150x65 / 6x2 1/2 | 165.1 x 76.1 / 6.500 x 3.000 | 70 / 2.76 | 238 / 9.37 | 113 / 4.45 | 122 / 4.8 | 95 / 3.74 | M16x 105-2 |

| 150x80 / 6x3 | 165.1x88.9 / 6.500 x 3.5 | 89 / 3.5 | 242 / 9.528 | 128 / 5.039 | 124 / 4.882 | 93 / 3.661 | M16x 105-2 |

| 150x32 / 6x1 1/4 | 168.3x42.4 / 6.625x1 660 | 51 / 2.01 | 255 / 10.04 | 88 / 3.46 | 123 / 4.84 | 96 / 3.78 | M16x 105-2 |

| 150x40 / 6x1 1/2 | 168.3x48.3 / 6.625x1.900 | 51 / 2.01 | 255 / 10.04 | 88 / 3.46 | 123 / 4.84 | 96 / 3.78 | M16x 105-2 |

| 150x50 / 6x2 | 168.3x60.3 / 6.625x2.375 | 64 / 2.52 | 255 / 10.04 | 102 / 4.02 | 123 / 4.84 | 96 / 3.78 | M16x 105-2 |

| 150x65 / 6x2 1/2 | 168.3x73.0 / 6.625x2.875 | 70 / 2.76 | 255 / 10.04 | 108 / 4.25 | 127 / 5.000 | 96 / 3.78 | M16x 105-2 |

| 200 x 50 / 8x2 | 219.1x60.3 / 8.625x2.375 | 64 / 2.52 | 310 / 12.2 | 104 / 4.09 | 153 / 6.02 | 124 / 4.88 | M20x 115-2 |

| 200 x 65 / 8x2 1/2 | 219.1x73.0 / 8.625x2.875 | 70 / 2.76 | 310 / 12.2 | 108 / 4.25 | 153 / 6.02 | 124 / 4.88 | M20x 115-2 |

| 200x65 / 8x2 1/2 | 219 1 x 76.1 / 8.625 x 3.000 | 70 / 2.76 | 310 / 12.2 | 115 / 4.53 | 152 / 5.98 | 124 / 4.88 | M20x115-2 |

| 200x80 / 8x3 | 219.1x88.9 / 8.625x3.500 | 89 / 3.5 | 310 / 12.2 | 127 / 5 | 152 / 5.98 | 124 / 4.88 | M20x 115-2 |

What are the advantages of using grooved pipe fittings in outdoor pipeline installation or long-distance pipeline installation?

Unlike traditional pipeline connections, grooved pipe fittings can be used in outdoor pipeline systems or long-distance pipeline installations without considering weather limitations, the need of electric tools or related power support. Besides, the installation of grooved pipe fittings is easy and highly efficient.

What are the industrial applications of grooved fittings and mechanical couplings?

The grooved fittings are commonly used in HVAC piping systems, fire sprinkler piping systems, wastewater treatment plants, and oil and gas transmission systems.