Mechanical Tee Threaded Outlet

Request a Quote

Grooved ductile iron pipe fittings

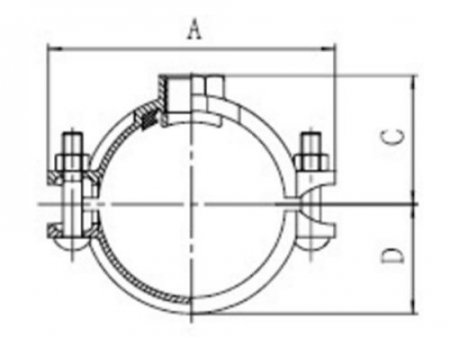

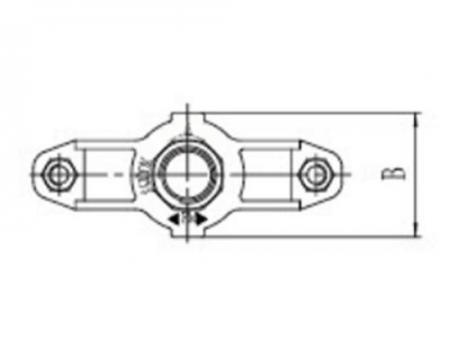

Mechanical tees threaded outlet consist of upper and lower housings, a gasket, and bolts/nuts, providing a simple and fast method for branch connection. The self-sealing structure of the gasket ensures permanent sealing. During field operations, mechanical tees can be tightly installed on the pipeline to ensure the accuracy of the branch outlet connection.

Features

- Mechanical tees threaded outlet provides an additional threaded outlet in existing piping.

- For new construction, the mechanical tee provides a way to bypass the use of a reducing tee.

- The mechanical tee may be easily converted into a cross when necessary.

Recommended Applications

Mechanical tees threaded outlet is suitable for piping systems, such as fire protection piping and sprinkler piping systems.

Key Specifications

- Available sizes: 2×1 inch~10×4 inch |DN50×25~DN250×65

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Material: ductile iron

Specifications

| Nominal Size | Pipe OD | Hole Dia | Dimensions | Bolt Size | |||

| mm/in | mm/in | Hole Cutting Measurement | mm/in | No.-Size / mm | |||

| A / mm | B / mm | C / mm | D / mm | ||||

| 50×15 / 2×1/4 | 60x21 / 2.375×0.827 | 38 / 1.5 | 118 / 4.64 | 74 / 2.91 | 55 / 2.17 | 40 / 1.57 | M10×55-2 |

| 50×20 / 2×3/4 | 60x27 / 2.375×1.063 | 38 / 1.5 | 118 / 4.64 | 74 / 2.91 | 60 / 2.36 | 40 / 1.57 | M10×55-2 |

| 50×25 / 2×1 | 60.3×33.7 / 2.375×1.315 | 38 / 1.5 | 118 / 4.64 | 74 / 2.91 | 60 / 2.36 | 40 / 1.57 | M10×55-2 |

| 50×32 / 2×1 1/4 | 60.3×42.4 / 2.375×1.660 | 45 1.77 | 118 / 4.64 | 74 / 2.91 | 60 / 2.36 | 40 / 1.57 | M10×55-2 |

| 50×40 / 2×1 1/2 | 60.3×48.3 / 2.375×1.900 | 45 / 1.77 | 118 / 4.64 | 74 / 2.91 | 60 / 2.36 | 40 / 1.57 | M10×55-2 |

| 65×15 / 2 1/2×1/4 | 73x21 / 2.875×0.827 | 38 / 1.5 | 132 / 5.2 | 74 / 2.91 | 62 / 2.52 | 47 / 1.85 | M12×70-2 |

| 65×20 / 2 1/2×3/4 | 73x27 / 2.875×1.063 | 38 / 1.5 | 132 / 5.2 | 74 / 2.91 | 62 / 2.52 | 47 / 1.85 | M12×70-2 |

| 65×25 / 2 1/2×1 | 73×33.7 / 2.875×1.315 | 38 / 1.5 | 132 / 5.2 | 74 / 2.91 | 64 / 2.52 | 47 / 1.85 | M12×70-2 |

| 65×32 / 2 1/2×1 1/4 | 73×42.4 / 2.875×1.660 | 51 / 2.01 | 132 / 5.2 | 82 / 3.23 | 64 / 2.52 | 47 / 1.85 | M12×70-2 |

| 65×40 / 2 1/2×1 1/2 | 73×48.3 / 2.875×1.900 | 51 / 2.01 | 132 / 5.2 | 82 / 3.23 | 64 / 2.52 | 47 / 1.85 | M12×70-2 |

| 65×50 / 2 1/2×2 | 73x60 / 2.875×2.375 | 51 / 2.01 | 132 / 5.2 | 84 / 3.23 | 75 / 2.95 | 47 / 1.85 | M12×70-2 |

| 65×15 / 2 1/2×1/4 | 76x21 / 3.000×0.827 | 38 / 1.5 | 135 / 5.31 | 72 / 2.83 | 62 / 2.52 | 48 / 1.89 | M12×70-2 |

| 65×20 / 2 1/2×3/4 | 76x27 / 3.000×1.063 | 38 / 1.5 | 135 / 5.31 | 72 / 2.83 | 64 / 2.52 | 48 / 1.89 | M12×70-2 |

| 65×25 / 2 1/2×1 | 76.1×33.7 / 3.000×1.315 | 38 / 1.5 | 135 / 5.31 | 72 / 2.83 | 64 / 2.52 | 48 / 1.89 | M12×70-2 |

| 65×32 / 2 1/2×1 1/4 | 76.1×42.4 / 3.000×1.660 | 51 / 2.01 | 135 / 5.31 | 85 / 3.35 | 66 / 2.60 | 48 / 1.89 | M12×70-2 |

| 65×40 / 2 1/2×1 1/2 | 76.1×48.3 / 3.000×1.900 | 51 / 2.01 | 135 / 5.31 | 85 / 3.35 | 66 / 2.60 | 48 / 1.89 | M12×70-2 |

| 65×50 / 2 1/2×2 | 76x60 / 3.000×2.375 | 51 / 2.01 | 135 / 5.31 | 84 / 3.23 | 76 / 2.99 | 48 / 1.89 | M12×70-2 |

| 80×15 / 3×1/2 | 88.9×21.3 / 3.500×0.825 | 38 / 1.50 | 146 / 5.75 | 74 / 2.91 | 66 / 2.60 | 55 / 2.17 | M12×70-2 |

| 80×20 / 3×3/4 | 88.9×26.7 / 3.500×1.050 | 38 / 1.50 | 146 / 5.75 | 74 / 2.91 | 66 / 2.60 | 55 / 2.17 | M12×70-2 |

| 80×25 / 3×1 | 88.9×33.7 / 3.500×1.315 | 38 / 1.18 | 146 / 5.75 | 74 / 2.91 | 70 / 2.76 | 55 / 2.17 | M12×70-2 |

| 80×32 / 3×1 1/4 | 88.9×42.4 / 3.500×1.660 | 51 / 2.01 | 146 / 5.75 | 86 / 3.39 | 73 / 2.87 | 55 / 2.17 | M12×70-2 |

| 80×40 / 3×1/2 | 88.9×48.3 / 3.500×1.900 | 51 / 2.01 | 146 / 5.75 | 86 / 3.39 | 77 / 3.03 | 55 / 2.17 | M12×70-2 |

| 80x50 / 3x2 | 88 9 x 60.3 3.500 x 2.375 | 64 / 2.52 | 146 / 5.75 | 96 / 3.78 | 80 / 3.15 | 55 / 2.17 | M12x70-2 |

| 80x65 / 3x2 1/2 | 89x76 / 3.500 x 3.000 | 64 / 2.52 | 146 / 5.75 | 99 / 3.90 | 84 / 3.31 | 55 / 2.17 | M12×70-2 |

| 100x25 / 4x1 | 108x33.7 4.250x1.315 | 38 / 1.5 | 172 / 6.77 | 72 / 283 | 76 / 2.99 | 64 / 2.52 | M12x75-2 |

| 100x32 / 4x1 1/4 | 108.0x42.4 / 4.250x1.660 | 51 / 2.01 | 172 / 6.77 | 82 / 3.23 | 76 / 2.99 | 64 / 2.52 | M12x75-2 |

| 100x40 / 4x1 1/2 | 108.0x48.3 / 4.250x1.900 | 51 / 2.01 | 172 / 6.77 | 82 / 3.23 | 76 / 2.99 | 64 / 2.52 | M12x75-2 |

| 100x50 / 4x2 | 108.0x60.3 / 4.250x2.375 | 64 / 2.52 | 172 / 6.77 | 95 / 3.74 | 78 / 3.07 | 64 / 2.52 | M12x75-2 |

| 100x15 / 4x1/4 | 114x21 / 4.500x0.825 | 38 / 1.5 | 178 / 7.01 | 74 / 2.91 | 83 / 3.27 | 69 / 2.72 | M12x75-2 |

| 100x20 / 4x3/4 | 114x27 / 4.500x1.063 | 38 / 1.5 | 178 / 7.01 | 74 / 2.91 | 83 / 3.27 | 69 / 2.72 | M12x75-2 |

| 100x25 / 4x1 | 114.3x33.7 4.500x1.315 | 38 / 1.5 | 178 / 7.01 | 74 / 2.91 | 86 / 3.99 | 69 / 2.72 | M12x75-2 |

| 100x32 / 4x1 1/4 | 114.3x42.4 / 4.500x1.660 | 51 / 2.01 | 178 / 7.01 | 86 / 3.39 | 87 / 3,43 | 69 / 2.72 | M12x75-2 |

| 100x40 / 4 x1 1/2 | 114,3x48.3 4.500 X1.900 | 51 / 2.01 | 178 / 7.01 | 86 / 3.39 | 89 / 3.51 | 69 / 2.72 | M12x75-2 |

| 100x50 / 4x2 | 114.3x60.3 4.500x2.375 | 64 / 2.52 | 178 / 7.01 | 100 / 3.94 | 94 / 3.7 | 69 / 2.72 | M12x75-2 |

| 100x65 / 4x2 1/2 | 114.3x76.1 4500x3.000 | 70 / 2.76 | 178 / 7.01 | 106 / 4.17 | 100 / 3.94 | 69 / 2.72 | M12x75-2 |

| 100x80 / 4x3 | 114.3x88.9 4.500x3.500 | 89 / 3.5 | 178 / 7.01 | 124 / 4.88 | 99 / 3.9 | 69 / 2.72 | M12x75-2 |

| 125x25 / 5x1 | 133.0 x 33 7 5.250x1.315 | 38 / 1.5 | 200 / 7.87 | 74 / 2.91 | 95 / 3.74 | 77 / 3.03 | M16x85-2 |

| 125x32 / 5x1 1/4 | 133.0 x 42.4 5.250x1.660 | 51 / 2.01 | 200 / 7.87 | 86 / 3.39 | 95 / 3.74 | 77 / 3.03 | M16x85-2 |

| 125x40 / 5x1 1/2 | 133.0x48.3 5.250x1.900 | 51 / 2.01 | 200 / 7.87 | 86 / 3.39 | 95 / 3.74 | 77 / 3.03 | M16x85-2 |

| 125x50 / 5x2 | 133.0 x 60.3 5.250x2.375 | 64 / 2.52 | 200 / 7.87 | 100 / 3.94 | 104 / 4.09 | 77 / 3.03 | M16x85-2 |

| 125x25 / 5x1 | 139.7x33.7 5.503x1.315 | 38 / 1.5 | 213 / 8.39 | 74 / 2.91 | 98 / 3.86 | 81 / 3.19 | M16x85-2 |

| 125x32 / 5x1 1/4 | 139,7x42.4 5.500x1.660 | 51 / 2.01 | 213 / 8.39 | 86 / 3.39 | 99 / 3.9 | 81 / 3.19 | M16x85-2 |

| 125x40 / 5x1 1/2 | 139.7x48.3 5.500 x1.900 | 51 / 2.01 | 213 / 8.39 | 86 / 3.39 | 111 / 4.37 | 81 / 3.19 | M16x85-2 |

| 125x50 / 5x2 | 133.0 x 60.3 5.250x2.375 | 64 / 2.52 | 213 / 8.39 | 100 / 2.19 | 106 / 4.17 | 81 / 3.19 | M16x85-2 |

| 125x65 / 5x2 1/2 | 139.0 x 76.1 / 5.500x3.000 | 70 / 2.76 | 213 / 8.39 | 108 / 4.25 | 110 / 4.33 | 81 / 3.19 | M16x85-2 |

| 150x25 / 6x1 | 165.1x33.7 / 6.500x1.315 | 38 / 1.5 | 239 / 9.41 | 74 / 2.91 | 112 / 4.41 | 95 / 3.74 | M16x 105-2 |

| 150x32 / 6x1 1/4 | 165.1x42.4 / 6.500x1.660 | 51 / 2.01 | 239 / 9.41 | 86 / 3.39 | 113 / 4.45 | 95 / 3.74 | M16x 105-2 |

| 150x40 / 6x1 1/2 | 165.1x48.3 / 6.500x1.900 | 51 / 2.01 | 239 / 9.41 | 86 / 3.39 | 115 / 4.53 | 95 / 3.74 | M16x 105-2 |

| 150x50 / 6x2 | 165.1x60.3 / 6.500x2.375 | 64 / 2.52 | 239 / 9.41 | 100 / 3.94 | 120 / 4.72 | 95 / 3.74 | M16x 105-2 |

| 150x65 / 6x2 1/2 | 165.1x76.1 / 6.500x3.000 | 70 / 2.76 | 239 / 9.41 | 108 / 4.25 | 124 / 4.68 | 95 / 3.74 | M16x105-2 |

| 150x80 / 6x3 | 165.1x88.9 / 6.500x3.500 | 89 / 3.5 | 239 / 9.41 | 126 / 4.96 | 123 / 4.84 | 95 / 3.74 | M16x 105-2 |

| 150x25 / 6x1 | 168.3 x 33.7 / 6.625x1.315 | 38 / 1.5 | 255 / 10.04 | 74 / 2.91 | 115 / 4.53 | 96 / 3.78 | M16x105 2 |

| 150x32 / 6x1 1/4 | 168.3x42.4 / 6.625x1.660 | 51 / 2.01 | 255 / 10.04 | 88 / 3.64 | 115 / 4.53 | 96 / 3.78 | M16x 105-2 |

| 150x40 / 6x1 1/2 | 168.3 x 48.3 6.625x1.900 | 51 / 2.01 | 255 / 10.04 | 88 / 3.64 | 115 / 4.53 | 96 / 3.78 | M16x 105-2 |

| 150x50 / 6x2 | 168.3x60.3 6.625x2.375 | 64 / 2.52 | 255 / 10.04 | 102 / 4.02 | 120 / 4.72 | 96 / 3.78 | M16x 105-2 |

| 150x65 / 6x2 1/2 | 168.3 x 73 6.625x3.000 | 70 / 2.76 | 255 / 10.04 | 108 / 4.25 | 122 / 4.80 | 96 / 3.78 | M16x 105-2 |

| 150x80 / 6x3 | 168.3 x 88.9 / 6.625x3.500 | 89 / 3.5 | 255 / 10.04 | 124 / 4.88 | 122 / 4.80 | 96 / 3.78 | M16x 105-2 |

| 200x25 / 8x1 | 219.1 x 33.7 / 8.625x3.315 | 38 / 1.5 | 310 / 12.21 | 73 / 2.87 | 135.5 / 5.35 | 115 / 4.53 | M20x 115-2 |

| 200x32 / 8x1 1/4 | 219.1 x42.4 / 8.625x1.660 | 51 / 2.01 | 310 / 12.21 | 82 / 3.23 | 135.5 / 5.35 | 115 / 4.53 | M20x 115-2 |

| 200x40 / 8x1 1/2 | 219.1 x48.3 / 8.625x1.900 | 51 / 2.01 | 310 / 12.21 | 86 / 3.39 | 135.5 / 5.35 | 115 / 4.53 | M20x 115-2 |

| 200x50 / 8x2 | 219.1 x 33.7 / 8.625x2.375 | 38 / 1.5 | 310 / 12.21 | 97 / 3.82 | 138 / 5.43 | 115 / 4.53 | M20x 115-2 |

| 200x65 / 8x2 1/2 | 219.1 x76.1 / 8.625x3.000 | 70 / 2.76 | 310 / 12.21 | 115 / 4.53 | 138 / 5.43 | 115 / 4.53 | M20x 115-2 |

What are the benefits of grooved fittings and mechanical couplings compared to traditional welded piping systems?

Grooved fittings and mechanical couplings offer several significant advantages over traditional welded piping systems, including faster installation, easier maintenance, improved flexibility and enhanced safety of the pipeline system.

What are the applications of grooved fittings and mechanical couplings?

Due to the excellent characteristics, these piping fittings are widely used in fire sprinkler piping systems, piping systems in food processing industries, industrial piping systems, and more.