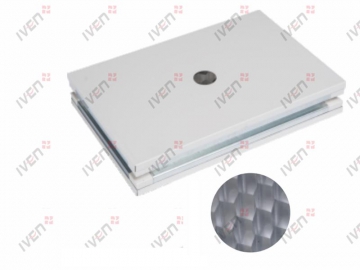

Multilayer Sandwich Panel Sheeting and Stacking Machine

Taking into consideration the production process of CCL and PCB, pressing and returning technology is used in the stack-up unit of multilayer sandwich panels, thus achieving an automatic production and low cost.

Capacity24 kilns/day, matching with 2 hot press

FeaturesCustom designing

Taking into consideration the different customer workshop layouts and requirements, the pCB stacking machine can be manufactured with custom designs and requirements, effectively avoiding problems of pitting, wrinkle and poor cutting during plate production processes.

Automatic production

The multilayer sandwich panel production line simultaneously carries out stack-up, breakdown, cutting, packaging and returning, making the production simple with a high degree of automation and low costs.

Low energy consumption

In order to decrease energy consumption and optimize the control system, the capacity of every unit is calculated, and custom design is essential.

Uses

Automatic arranging of plates

- Stacking mode: automatic stack-up

- Capacity of pressing machine: 24 /day

- Stacking speed: 12 seconds/layer

Uses

Plate cutting

- Cutting mode: automatic cutting after unwinding roll

- Cutting accuracy: length error±1mm/m, diagonal error±1.5mm/m

- Cutting speed: decided by pressing machine

Separating area of inner paper

Separating area of inner paper High-speed exchanging area of bottom plates

High-speed exchanging area of bottom plates Separating elevator

Separating elevator Material turnover

Material turnover