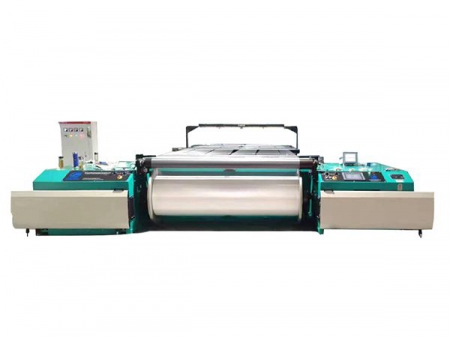

Warping Machine

Request a Quote

for warp knitting

The computerized direct warping machine comes with quality beams for further processing in warp knitting. The microcomputer control system continuously monitors the diameter of the warp beam during the warping process and adjusts the tension in real time, ensuring consistent diameter (outer circumference) and length of the warp beam.

Applications

Warping machine is suitable for processing short fiber yarns such as nylon, polyester filament, low-elastic yarn, viscose yarn, cotton yarn, and acrylic yarn.

Features

- The warping machine has a novel design, simple operation, intelligent recognition, and automatic data saving for various parameters.

- Automatic speed tracking control, automatic detection mechanism, and power failure protection system.

- The grouped parameters identical to the master warp beam can be copied based on the sample of the master warp beam.

- The computer continuously monitors the diameter, length, and laps of the warp beam in real time, controls the smooth tension of the yarn, and ensures the consistent diameter (outer circumference) and length of the grouped warp beams.

- The loading and unloading of the warp beams are pneumatically driven, and the lifting is done in a straight line, ensuring smooth operation and precise positioning. The main spindle brake uses pneumatic brakes.

- The master copy system ensures absolutely identical beams in circumference.

Specifications

| Line speed | 80-980m/min |

| Warp beam size | 21"×30" (inch) 21"×40" (inch) 21"×42" (inch) |

| Beam lift, clamp and brake | Pneumatic control |

| Motor power | 11kW AC frequency conversion control |

| Tension roller | Servo motor, frequency conversion control |

| Control method | Micro-computer real-time monitoring and display |

| Copy precision | Perimeter error of the same group of beams is less than 5mm |

| Max. counting range | 99999m (circle) |