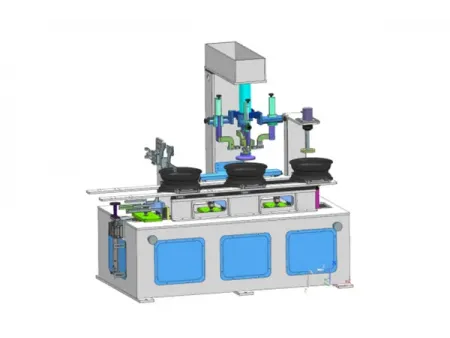

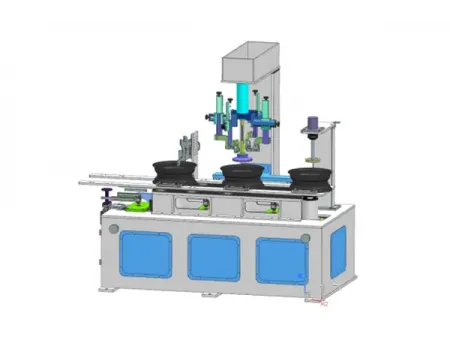

Steel Wheel Assembly Welder

Multi-head welding machine used to weld the wheel disc to the wheel rim

The steel wheel assembly welder is a multi-head welding machine designed to weld the wheel disc to the wheel rim, forming a solid and durable steel wheel. This four head combination welder utilizes four CO₂-protected welding heads to simultaneously weld the inner circumferential seams of the disc and rim independently in a single operation. Key advantages include high energy efficiency, minimized deformation, and superior welding strength, with all four weld seams completed in a single pass, ensuring consistent quality and a streamlined production process.

Process Flow

- Welding

Specifications

| Model | ||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW |

| Wheel width | 5-8.25inch | 8.25-11.75inch |

| Wheel diameter | 12-19inch | 16-25inch |

| Voltage | 380V±10%,3phase,50HZ | 380V±10%,3phase,50HZ |

| Rotation speed of worktable (stepless adjustable) | 0.1-2rpm | 0.1-2rpm |

| Motor torque | 2.8N.M | 3.8N.M |

| Compressed air | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Axial adjustment | 80mm | 100mm |

| Radial adjustment | 140mm | 160mm |

| Welding torch angle | 30-45° | 30-45° |

| Welding voltage (stepless adjustable) | 0-30V | 0-30V |

| Welding current (stepless adjustable) | 0-500A | 0-500A |

| Welding wire diameter | Ø1.2-Ø1.6mm | Ø1.2-Ø1.6mm |

| CO₂ consumption (adjustable based on the product) | 10L/min×4 | 15L/min×4 |

Features

- The welding head can be adjusted in four directions: up/down, left/right, forward/backward, and angle, allowing precise positioning relative to the workpiece for optimal weld quality.

- The upper section features a platform with safety railings, where four welding units are mounted, accessible via a staircase. This design combines structural integrity with aesthetic appeal.

- The negative electrode of the welding machine is connected to the rotating shaft via eight 200A copper carbon brushes, while the positive electrode connects to the torch, ensuring excellent conductivity and high welding quality.

- The rotation speed of the workpiece is infinitely adjustable, allowing precise control for different welding requirements.

- Combining detection, welding, and grinding into one system saves space and enhances production efficiency.

- An upper-layer smoke extraction port connects to a dust collection system, helping to maintain a clean working environment.

- Located on the lower layer, the four-station feeding rack is cylinder-driven and equipped with positioning clamps for accurate workpiece alignment.

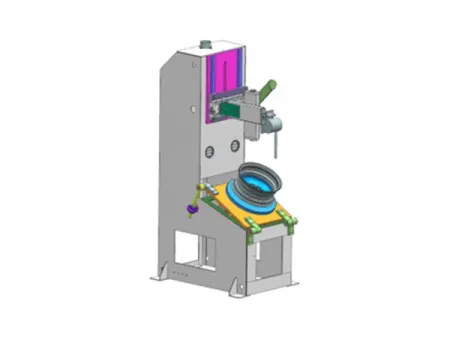

The submerged arc welding machine is designed to weld wheel rims to wheel discs in steel wheel production. It consists of a main frame, sliding platform, worktable, chuck, and welding unit. Once the chuck securely positions and clamps the rim and disc, the sliding platform moves the welding torch along the connection area, ensuring a precise, stable weld at the joint. This method enhances joint strength and minimizes the need for additional finishing, providing a seamless weld for durable wheel assembly.

Process Flow

- Welding

Specifications

| Model | ||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW |

| Wheel width | 5-8.25inch | 8.25-11.75inch |

| Wheel diameter | 12-19inch | 16-25inch |

| Rated input current | 70A | 83A |

| Rated input voltage | 50V | 44V |

| Rated duty cycle | 100% | 100% |

| Output no-load voltage | 96V | 87V |

| Current adjustment | 40-800A | 50-1000A |

| Voltage adjustment | 25-60V | 20-50V |

| Power factor | ≥0.88 | ≥0.88 |

| Welding wire diameter | 2-6mm | 2-6mm |

| Protection class | IP21S | IP21S |

| Insulation class | H/B | H/B |

| Machine weight | 90kg | 95kg |

Features

- Supports a variety of welding methods, including coarse wire, fine wire, flux-cored wire, strip, and dual-wire single-arc welding

- Multiple welding units can be connected in parallel to achieve high current output for demanding applications

- Equipped with overheat, open circuit, and short circuit protection to ensure safe and stable operation

- Allows storage of up to 10 welding specifications for easy recall and consistency in production

- Features multiple external interfaces, facilitating integration into dedicated welding setups

- Offers the option to add group control functionality for coordinated operation of multiple units