Steel Wheel Production Tooling & Die Sets

Tool sets used in steel wheel production line

Our company offers specialized tooling & die sets tailored for steel wheel production lines, with a strong focus on innovative design and precision. Backed by a dedicated R&D and design team, we provide customized tooling solutions that meet specific client requirements, using advanced design software and technology to ensure each die is optimized for high-efficiency production and exacting standards from the design stage.

Aoguan provides durable, high-precision tooling solutions tailored to the specific requirements of wheel manufacturing. Our custom die sets and tooling are designed to boost efficiency in steel wheel production, helping your operation maintain a competitive edge in today’s dynamic market.

- Customized solutions: Whether standard or uniquely specified dies, we respond promptly to client needs, delivering optimal designs tailored to the unique requirements of steel wheel production.

- Optimized design process: Utilizing digital design and simulation, our team thoroughly tests and refines each tooling component during the design phase, ensuring high precision and extended durability for all steel wheel manufacturing applications.

- Continuous innovation: We are committed to ongoing process improvements and technological advancements, enhancing tooling efficiency and stability to help clients in the steel wheel industry achieve greater productivity and profitability.

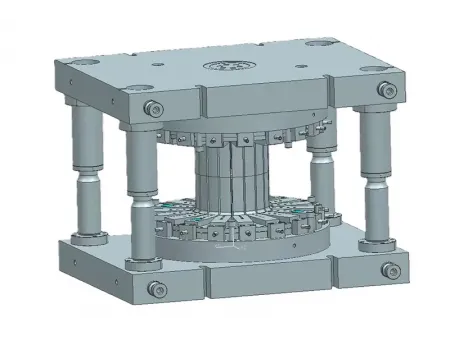

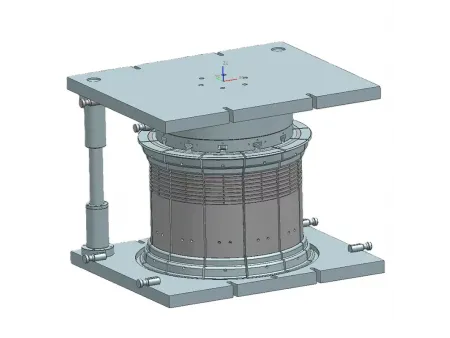

34-42 inch diameter, 20-30 inch width agricultural wheel rim expanding mold is designed for expanding agricultural wheel rims, with a flexible setup that separates the groove base and rim expansion blocks. By adjusting the rim expansion block, rims of the same diameter but different widths can be expanded. Each additional layer of the groove base expansion block increases the diameter by 2 inches, while removing a layer decreases it by 2 inches.

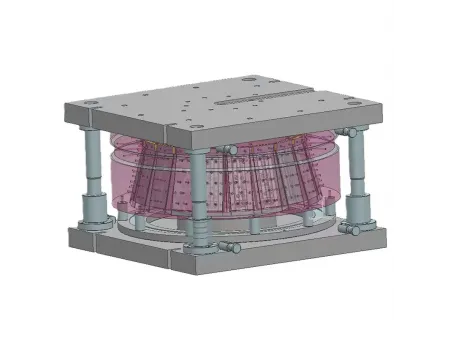

8.5-24 steel rim compression mold features a 19-segment shrinking module structure with T-shaped sliding rails, this mold ensures precise centripetal accuracy during the shrinking process.

Driven by a servo motor for precise indexing, the automatic valve hole punching and extrusion tooling is integrated with the punching machine to enable fully automated production of valve holes.

Cylinder expanding mold is used for expanding cylindrical workpieces with a material thickness of 8mm or more, delivering expansion accuracy within ±0.5mm.

8.5-24 steel expanding mold is constructed with a 17-segment expansion module and improves expansion accuracy by 0.4mm over the modules with 12-segment designs.

Large tubeless rim expanding mold frame uses an 18-segment structure with an 18-faceted cone surface, allowing uniform surface contact and force distribution. Expansion accuracy is maintained within 0.4mm.

Wheel disc stamping die is designed for stamping wheel discs, ensuring consistent shaping and structural integrity.

Thermal expansion and pressing mold is primarily used for construction vehicle rims and allows for rapid forming in a heated, red-hot state by first flaring the rim and then pressing it into desired shape.

Our production facilities are equipped with advanced machinery, enabling us to handle the full manufacturing process from design to large-scale production. With over 60 modern machines, including CNC lathes, vertical machining centers, horizontal machining centers, and gantry machining centers, we ensure precision and quality in every mold we produce.

- Efficient production processes: Our complete production lines and standardized operations, from raw material sourcing to each step of mold fabrication, are controlled and optimized for quality.

- Quality assurance: We utilize advanced inspection equipment and a rigorous quality management system, conducting strict testing at every stage of mold production to meet the highest standards.

- High production capacity: Supported by advanced manufacturing capabilities and modern facilities, we can fulfill orders of various scales, ensuring on-time delivery without compromising on quality.

Tooling & Dies for Wheel Rim Production

- Wheel Rim Flaring Die

- Wheel Rim Roll Forming Die

- Wheel Rim Roll Forming Die

- Wheel Rim Roll Forming Die

- Wheel Rim Expanding Die

- Wheel Rim Valve Hole Punching Tools

- Wheel Rim Valve Hole Punching Tools

- Wheel Rim Valve Hole Punching Tools

- Wheel Rim Valve Hole Punching Tools

Tooling & Dies for Wheel Disc Forming

- OP10 Wheel Disc Stamping Die

- OP20 Wheel Disc Stamping Die

- OP30 Wheel Disc Stamping Die

- OP40 Wheel Disc Stamping Die

- OP50 Wheel Disc Stamping Die

- OP60 Wheel Disc Stamping Die

- OP70 Wheel Disc Stamping Die

- OP80 Wheel Disc Stamping Die

Tooling & Dies for Steel Wheel Assembly

22.5inch Wheel Assembly Press Fitting Die