Vertical Glass Accumulator

Vertical glass accumulators are used to temporarily store glass panels during processing, helping maintain a smooth production flow across different stages of the line. They’re especially useful when working with rigid materials like glass and help save floor space by using a vertical design. Depending on production needs, they can hold 15, 30, or even 50 panels, offering flexibility for automated operations and reducing unnecessary downtime.

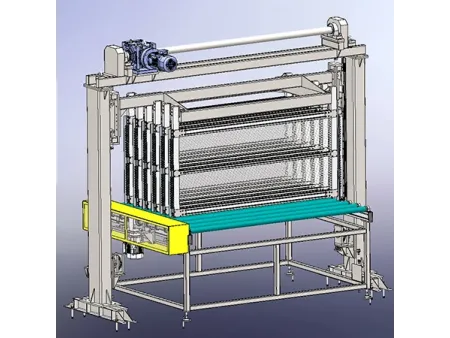

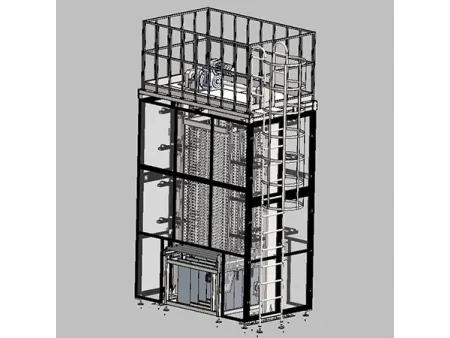

Our vertical glass accumulators are designed to optimize the workflow between processing stages by temporarily holding glass panels in a vertical position. It consists of two main functional sections that work together to ensure smooth and efficient production: the conveyance unit and the accumulation unit.

- Transports glass panels using rubber-coated rollers.

- Motion is driven by a gear motor and timing belts for reliable, consistent speed.

- Adjustable roller spacing to accommodate panels of various sizes.

- Conveyor speed can be adjusted via an inverter for better production control.

- Equipped with a photoelectric sensor to detect the glass position and ensure precise stopping.

- Includes a transparent observation window made of PC board over the drive area for easy monitoring and maintenance access.

- Controls vertical stacking and release of glass panels via a gear motor and chain system.

- Available in configurations that hold up to 15, 20, or 40 panels, depending on production needs.

- Accumulation speed can be adjusted with an inverter to match workflow demands.

- Enclosed in a dust-proof casing made with aluminum profiles and clear PVC panels to ensure safety and keep the area clean.