Metal Bellows Accumulator

Energy storage components for precision fluid control in hydraulic and pneumatic systems across automotive and industrial sectors

A precision metal bellows accumulator is a high-accuracy energy storage and dynamic regulation device that uses a metal bellows as its core isolation element. It is widely applied in hydraulic and pneumatic systems that require high-frequency response, extremely low leakage, and clean operating environments.

Its precision is reflected in manufacturing accuracy, dynamic response capability, sealing reliability, and highly stable volume control. Compared with traditional piston-type or diaphragm-type accumulators, metal bellows accumulators are better suited for applications with demanding reliability and precision requirements.

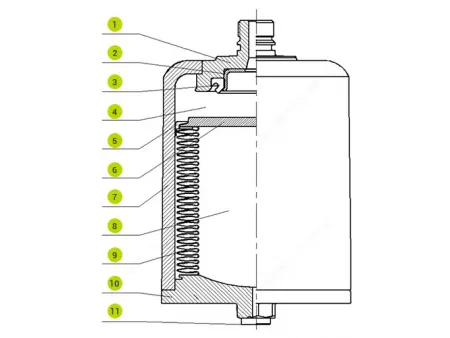

The precision metal bellows accumulator is centered around the metal bellows assembly, and consists of a high-pressure end cap, metal bellows, inflation end cap, fluid (or gas) port, inflation valve, and other functional components. Its operating principle relies on the flexible deformation of the metal bellows to achieve gas–medium isolation and efficient energy conversion.

- Oil end cap

- Retaining ring

- Sealing ring

- Oil chamber

- Guide ring

- Sealing cover

- Cylinder

- Gas chamber

- Bellows

- End cap

- Gas sealing cap

- Oil end cap

- Support sleeve

- Bellows

- Oil chamber

- Sealing cover

- Cylinder

- Guide ring

- Gas chamber

- Gas sealing cap

- Energy storage

When system pressure exceeds the preset gas pressure of the accumulator, the medium pushes the bellows to compress the internal gas. As the volume decreases, gas pressure increases (following Boyle’s Law), converting system energy into stored gas potential energy. - Energy release

When system pressure drops below the internal gas pressure of the accumulator, the bellows expands under gas pressure, pushing the medium back into the system and releasing the stored energy. - Precision

The expansion displacement of the bellows is linearly related to pressure change (linearity ≤ 0.5%), enabling highly accurate control of volume variation. Since there are no friction components (the bellows is rigidly connected to the end caps with no sliding parts), response delay is ≤ 5 ms, making it suitable for absorbing high-frequency pulsations, such as 10–100 Hz pressure fluctuations.

The PV curve (Pressure–Volume curve) of an accumulator is a graphical representation describing the change in internal fluid volume V as system pressure P varies. It is typically used to analyze and understand accumulator performance, especially its dynamic behavior during energy storage and release.

- Precharge pressure (P0): Gas pressure inside the accumulator when there is no pressure on the oil/fluid side.

- Working pressure (P1): Maximum operating pressure that the accumulator can reach under normal working conditions.

- Design pressure (P2): Maximum pressure that the accumulator is structurally designed to withstand.

- Effective volume (V0): Gas chamber volume of the accumulator under precharged condition.

- Working temperature: −40°C to 120°C

- Bursting pressure: ≥ 80 MPa

| Characteristic | Precision Metal Bellows Accumulator | Piston-Type Accumulator | Diaphragm-Type Accumulator |

| Leakage rate | ≤ 1 × 10⁻⁹ Pa·m³/s | Higher (possible wear of friction pairs) | Lower (but rubber aging may cause leakage) |

| Response time | ≤5ms | ≥50ms | ≤20ms |

| Volume linearity | ≤0.5% | ≥2% | ≤1% |

| Cleanliness | No particle contamination (metal bellows structure) | Possible metal particle generation | Possible rubber particle generation |

| Fatigue life (cycles) | ≥ 1,000,000 | ≥ 500,000 | ≥ 300,000 |

| Applicable pressure | 0.5–31.5 MPa (high-pressure models up to 70 MPa) | 0.5-31.5 MPa | 0.5-25 MPa |

The high precision, exceptional cleanliness, and fast response characteristics of precision metal bellows accumulators make them the preferred solution in the following fields:

- Semiconductor & electronics manufacturing

Used in hydraulic drive systems of wafer lithography machines and ion implantation equipment to absorb high-frequency pressure pulsations (preventing wafer processing accuracy deviation). With zero leakage and no particulate contamination, they meet ultra-clean requirements such as Class 10 cleanroom environments. - Precision machine tools & robotics

In spindle hydraulic balancing systems, they compensate instantaneous pressure fluctuations (such as load changes during high-speed cutting), ensuring spindle speed stability (fluctuation ≤ ±1 rpm). In collaborative robot joint drives, they provide instantaneous energy compensation, reducing servo motor power consumption. - Medical equipment

In hydraulic actuators of surgical robots (such as laparoscopic instrument drives), precise volume control enables millimeter-level motion accuracy. In the hydraulic circuits of hemodialysis equipment, the absence of rubber components prevents contamination risks to blood. - Aerospace & defense

In satellite attitude control hydraulic actuators, lightweight titanium bellows and high reliability allow stable operation under −50°C to 150°C, storing and releasing energy to support attitude adjustment. In missile guidance systems, they absorb pressure shocks caused by engine vibration, ensuring control accuracy.

Production capacity

- Equipped with 3 automated production lines

- Planned monthly capacity: 100,000 units

- Key equipment includes: Bellows forming machines, vacuum electron beam welding machines, micro-beam plasma welding machines, ultrasonic flaw detection equipment, helium leak detection systems, PV online testing systems, and medium-frequency inverter sealing welders

Cleanroom requirements for accumulator production

- Cleanliness level: Class 1,000,000 cleanroom

- Temperature & humidity: Temperature 18–28°C, humidity 45–65%

- Air exchange rate: Not less than 12 air changes per hour

- Hydraulic oil cleanliness: NAS cleanliness testing applied, injected hydraulic oil must meet ≤ NAS 8 level

- Internal cleanliness: Gravimetric method applied before oil filling; internal contamination must be ≤ 4 mg

- Plasma beam welding

- Air tightness testing

- PV performance testing

- Ultrasonic flaw detection