Anodized Aluminum Coil

Anodized Aluminum Coil

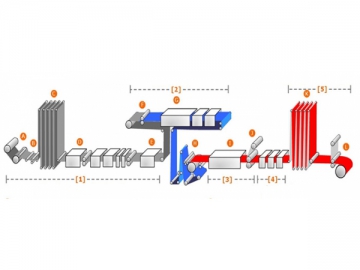

美工放图:

阳极氧化3.jpg阳极氧化

阳极氧化

Application

Anodizedaluminum coils are widely used in construction and decorations (such asaluminum ceiling, ACP, curtain wall plate, fire-proof sheet, etc), electricappliance, lighting decoration, reflector material for solar energy, furnituredecoration, automotive decoration, etc.

Features

Environmentfriendly, safe and reliable, good color and weathering-proof, anti-

Aluminum

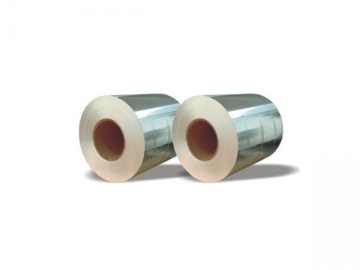

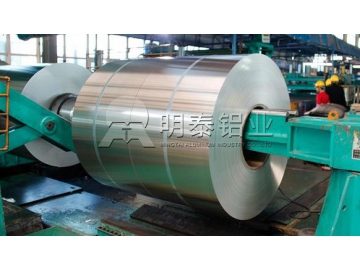

Thickness range: 0.18mm-0.60mm

Alloy:

1 series, for industries of lighting and solar energy

3 series, forbuilding materials such as ceiling and ACP

5 series, forhigh-performance products such as aluminum ceiling, curtain wall and etc.

Width range: ≤1250mm

Others: the product is usually filmed to protect thelayer of of

Technical parameters

| No. | Test Item | Standard | National Standard Requirement | Test result |

| 1 | Coating thickness | GB/T6462 | ≥4µm | 5µm |

| 2 | Chromatism | GB/T11942 | as agreed | △ E≤2.0 |

| 3 | Aperture covering | GB/T8753.1 | ≤30mg/dm2 | ≤30mg/dm2 |

| 4 | Solvent resistance | GB/T8013.2 | ≤1H | No change |

| 5 | Erosion resistance | GB/T12967.3 | ≥ Grade 9 | ≥ Grade 9 |

| 6 | Abrasion resistance | GB/T12967.1 | ≥300g/µm | ≥300g/µm |

| 7 | Glossiness | GB/T20503 | as agreed | ≤5 |

| 8 | Hardness | GB/T6739 | ≥1H | 3H |

| 9 | Boiling water proof | GB/T8013.2 | 20min | No change within 2h |

| 10 | Detergent resistance | GB/T6682 | ≥72h | ≥100h |

| 11 | Insulativity | GB/T8754 | as agreed | 220-500 ∨ ∕200-500MΩ |

| 12 | Ultraviolet light resistance | GB/12967.4 | ≥80 | No change |

| 13 | Artificial light resistance | GB/T8013.1 | ≥6 | ≥6 |

| 14 | Film continuity | GB/T8754 | as agreed | good |