Vertical Dryer

Product Production

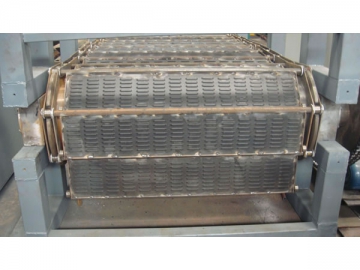

The vertical dryer is one of the important equipment in briquette production line, designed for drying various types of formed briquettes, including coal briquette, mineral powder briquette, iron powder briquette, fluorite powder briquette, etc. This vertical drying machine is specially designed relying on the drying characteristics of industrial coal briquettes and gravity principle, successfully avoiding the problems existing in today’s coal briquette dryers such as large investment and floor area as well as high failure rate.

The moisture content of coal powder briquette is generally 12-14%. After being dried by this coal briquette drying equipment, it can be reduced to be 2-4% which meets the intensity requirements for storage and transportation. Through further improvement, the moisture content can be lowered to less than 1.5%. It can also be used to dry ore briquette and coal rod.

Features

1. Compared with chain conveyor dryer, the investment amount of this vertical dryer decrease by 50% and floor space reduces by 67% to 80%.

2. The energy consumption and operating cost are considerably reduced.

3. This cone dryer is easy to combine with other equipment in the briquette production line and realize automation.

4. This fluorite powder briquette dryer features easy operation and simple maintenance. To be specific, this drying machine needs no daily maintenance in that it has no mechanical motion components.

5. It is favorable for continuous operation with high efficiency and large capacity.

6. YUKE vertical dryer can save considerable labors and reduce labor intensity for you.

Working Principle

The formed briquettes are conveyed to the top of the dryer by belt conveyor and evenly distributed on the total across section by material distributing device. As the cone rotates, the coal briquettes will travel down along their orbit under gravity while conducting heat exchange with the strong hot wind blew from the bottom of the equipment. The water vapor of evaporated from the briquettes will be blew away along the wind. Through two hours evaporating process, the briquettes can be fully dried.

| Models | Capacity (t/h) | Power (kw) |

| 3-6 | 22 | |

| 8-10 | 30 | |

| 12-15 | 30 | |

| 15-20 | 37 |

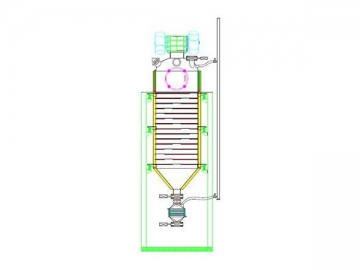

Flow Chart

Flow Chart of Vertical Dryer

1. Material Feeding By Belt Conveyor

2. Air Inlet 1

3. Fan

4. Motor

5. Working Platform

6. Air Inlet 2

7. Discharging By Belt Conveyor

8. Concrete Pillars

9. Air Inlet 1

10. Air Inlet Connector 2

11. Air Inlet Connector 1

12. Air Bellow

13. Fan

14. Blast Pipe of Fan

15. Air Inlet 2

16. Vertical Dryer Sketch Drawing

17. Furnace