Belt Dryer

Production

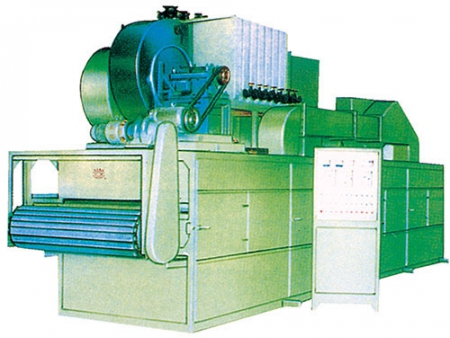

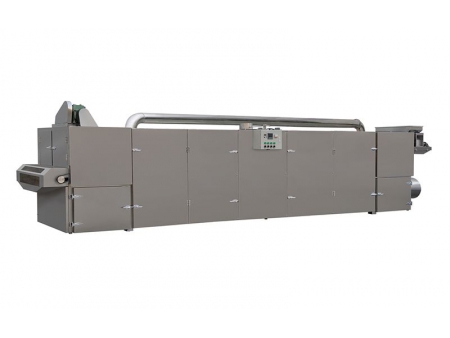

The belt dryer is a kind of industrial drying machinery that is used for continuous drying of sheet-shaped, bar-shaped and granular materials such as coal briquette, mineral briquette, fluorite powder briquette, etc. by means of electrical heating, steam heating and hot air heating. In addition, this belt type drying machine can also be used to dry cassava sheet, vegetables, fruits, medicinal materials, foods, etc. With high drying efficiency and excellent effect, our mesh belt dryer can perfectly meet your drying requirements.

Features

1. YUKE belt dryer can achieve the best drying effect by adjusting air flow, heating temperature, material dwell time and feeding speed.

2. This food drying equipment comes with flexible configuration. Belt washing system and material cooling system can be flexibly equipped.

3. Most of air used to heat the materials can be recycled, thus saving a large amount of energy.

4. The belt briquette dryer is provided with special air distributing device which enables the hot air to be uniformly distributed.

5. The heat source can adopt steam, conduction oil, fuel gas, etc.

6. Our belt dryer will be an ideal choice for you with small floor space and investment while large capacity and evaporation intensity.

Working Principle

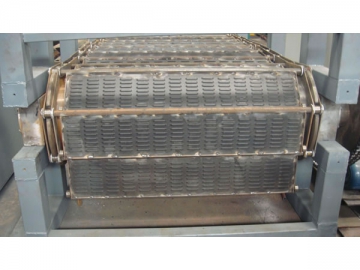

The materials to be dried are continuously and evenly applied through an infeed chamber onto a perforated belt. Under the force of drive unit, the steel wire mesh belt with 12-60 meshes carries the materials through the drying area where the drying gas lows through or over the material and dries it. The water vapor will be exhausted from the exhaust holes.

The drying chamber can be divided into several sections. To save space, the belt dryer can be made into multi layers. Commonly, this multilayer drying equipment has two chambers and three layers, or two chambers and five layers, with length of 6-40m and effective width of 0.6-3.0m.

Technical Parameters| Models | ||||||||

| Belt Width(mm) | 600 | 800 | 1000 | 1200 | 1600 | 2000 | 2400 | 3000 |

| Length of drying section(m) | 6-12 | 6-12 | 6-16 | 8-16 | 8-22 | 10-26 | 12-30 | 12-40 |

| Length of feeding section(m) | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Length of driving section(m) | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Drying area(m2) | 3.6-36 | 4.8-48 | 6-80 | 7.2-96 | 12.8-105.6 | 20-260 | 28.8-360 | 36-600 |

| Layer No. | 1-5 | |||||||

| Space between layers(mm) | 400-600 | |||||||

| Loading capacity | 90-200 Kg/m 2 | |||||||

| Operating temperature | Carbon steel≤400 ℃ Stainless stell≤ 600 ℃ | |||||||

| Evaporation intensity | 5-20kg/m2.h | |||||||

| Heat source | Hot air, electricity and steam | |||||||

| Operating speed | 0.06-1m/min | |||||||

| Power (kw) | 1.1-2.2 | 1.1-2.2 | 1.1-2.2 | 1.1-3 | 1.5-3 | 1.5-4 | 3-7.5 | 5-11 |

| Corollary equipment | Conveyor, air heater, dust collector, induced draft fan, etc. | |||||||

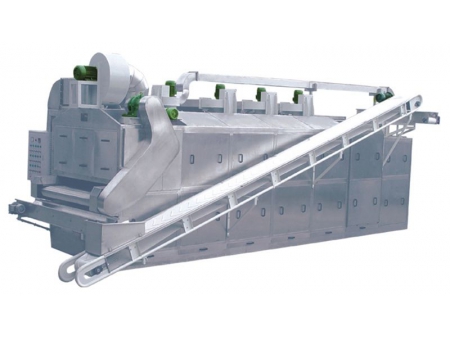

Flow Chart

Process Flow of Belt Dryer

1. Belt Dryer

2. Smoke Exhaust Pipe

3. Chain Wheel

4. The Third Layer

5. The Second Layer

6. The First Layer

7. Hot Wind Chamber

8. Frame Structure

9. Conveyor

10. Ground Plane