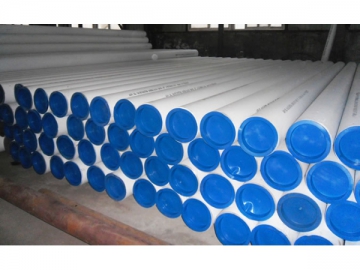

Anti-Corrosion Steel Pipe

Various steel pipe external coating projects are currently implemented by our company including single-layer/double-layer FBE, 2PE, 3PE, 3PP and other anti-corrosion coatings with the performed standards such as DIN30670, DIN30671, DIN30678, ANSI/AWWA C210-2003, ANSI/AWWA C213, CAN/CSA-Z245.21-M92, NF A49-709, NF A49-710, API RP 5L2, SY/T4013-2002 and SY/T0315-97 etc.

DIN 30670: Polyethylene coatings of steel pipes and fittings

ANSI/AWWA C213 standard for Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines

AWWA C210: Liquid-Epoxy Coating Systems for the Interior and Exterior of Steel

CAN/CSA-Z245.21-M92: External Polyethylene Coating for Pipe

Purpose

The outer coating is mainly used for oil transportation by pipeline corrosion protection of buried before; the inner coating reduces drag, reducing pipeline investment and operation and maintenance costs.

Pipe external corrosion

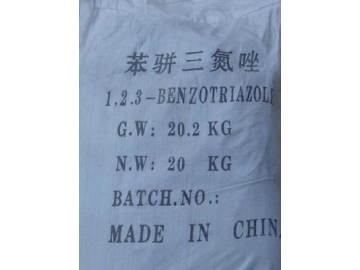

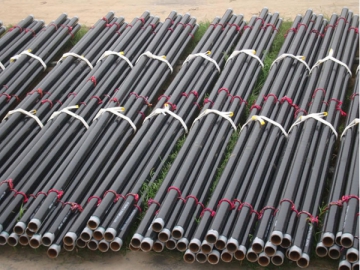

1. Single FBE corrosion (FBE)

Single-layer FBE Coating Epoxy powder layer because of its excellent corrosion resistance, insulation resistance and long service life and become an advanced anti-corrosion coating of the outer pipe. Sub-ordinary nature (thickness: 300 ~ 400um) and enhanced (thickness: 400 ~ 500um) two kinds.

2. Double FBE corrosion (2FBE)

Double epoxy powder coated outer coating is a composite structure, consisting of anti-corrosion epoxy powder primer and epoxy powder resistant to mechanical damage the surface layer of a coating film is completed. Normal sex (thickness ≥ 620um); enhanced (thickness ≥ 800um)

3. Two polyethylene / polypropylene anticorrosion (2PE/2PP)

Two polyethylene / polypropylene layer with good corrosion resistance, insulation resistance, long service life and resistance to mechanical damage. Sub-normal and enhanced thickness according to pipe size varies: Common Min1.8mm; enhanced minimum 2.5mm.

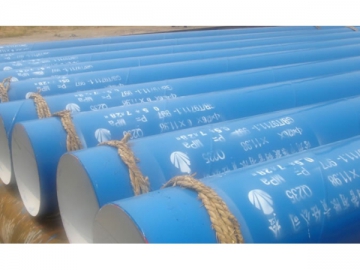

4. Three layer polyethylene / polypropylene anticorrosion (3PE/3PP)

Three layer polyethylene / polypropylene layer with excellent corrosion resistance, insulation resistance, longer service life and a certain degree of resistance to mechanical damage of the coating has been widely used in various large-scale projects of the corrosion in the pipeline. Common type and strengthened type two, thickness of the pipe size varies: Common minimum thickness 1.8mm; enhanced minimum thickness of 2.5mm.

| Nominal Diameter Range | Outside Diameter Rang (mm) | Coating Type | Coating Layer | Coating Thickness |

| DN100~600 | 114.3~609.6 | 3PE: Three Layers Polyethylene | Inside Layer: Epoxy (Green) | 2.0~4.5mm |

| Mid Layer: Adhesive (White) | ||||

| Outside Layer: Polyethylene (Black) | ||||

| 2PE: Two Layers Polyethylene | Inside Layer: Adhesive | 2.0~4.5mm | ||

| Outside Layer: Polythene | ||||

| DN80~600 | 88.9~609.6 | FBE: Epoxy | Epoxy | 200~400um |

| 2FBE: Two Layers Epoxy | Inside Layer: Epoxy (Green) | 400~800um | ||

| Outside layer: Intensity Epoxy (Sage Green) | ||||

| DN100~600 | 114.3~609.6 | 3PP: Three Layers Polypropylene | Inside Layer: Epoxy(Green) | 2.5~3mm |

| Mid Layer: Adhesive (White) | ||||

| Outside Layer: Polypropylene (White) |