Bulk Material Belt Conveyor

The bulk material belt conveyor is a highly efficient solution that is widely used in various industries. It is designed to transport materials seamlessly from the start of the process to the endpoint, making it a pivotal element in the production lines such as the cement production. The belt conveyor operates on the principle of friction-driven movement, which allows for the smooth transfer of materials. Apart from bulk materials, it can also efficiently move finished products, making it a key component in industrial production lines.

The belt conveyor system plays a critical role in streamlining the transportation of materials between production machinery. It enables a continuous and automated workflow that not only boosts production efficiency but also significantly reduces manual labor. The belt conveyor is adaptable to different industrial environments and can handle a wide range of materials, from raw bulk to finished goods. This makes it an essential tool in achieving streamlined operations and enhancing productivity, especially in the cement production lines where Sinomaly excels.

Ores, gravel, coal, coke, cement, sand, pebbles, limestone, slag, etc.

| Belt Width (mm) | Speed (m/s) | |||||||||

| 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | 5.0 | 6.5 | |

| Conveying Capacity (m³/h) | ||||||||||

| 500 | 69 | 87 | 108 | 139 | 174 | 217 | ||||

| 650 | 127 | 159 | 198 | 254 | 318 | 397 | ||||

| 800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | |||

| 1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | ||

| 1200 | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2971 | ||

| 1400 | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 4130 | ||

| 1600 | 2186 | 2733 | 3444 | 4373 | 5466 | |||||

| 1800 | 2795 | 3494 | 4403 | 5591 | 6989 | 9083 | ||||

| 2000 | 3470 | 4338 | 5466 | 6941 | 8676 | 11277 | ||||

| 2200 | 6843 | 8690 | 10863 | 14120 | ||||||

| 2400 | 8289 | 10526 | 13158 | 17104 | ||||||

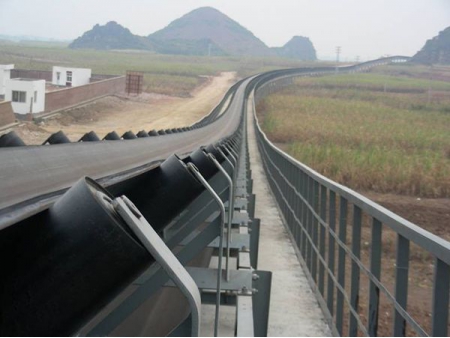

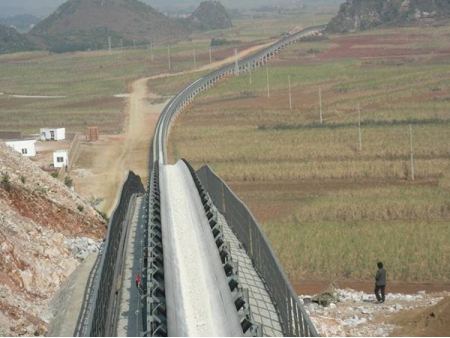

- Our belt conveyors are adaptable to any requirement. From traditional designs to specialized options for slopes or turns, equipped with accessories like side barriers to meet specific process needs.

- The belt conveyor’s components, particularly pulleys, are built for smooth operation and longevity, reducing the need for maintenance.

- Made from rubber, PVC, and PU, these belt conveyors are capable of handling everything from general cargo to materials requiring oil or corrosion resistance.

- Vulcanization techniques for belt joints significantly enhance durability and wear resistance.

- Our tensioning devices come in several forms, including screw, trolley, vertical, hydraulic, and winch types. We design these devices to ensure optimal tension, contributing to the conveyor's lifespan and ensuring smooth startup and braking performance.